If you love electronics and you enjoy geeking out on electronics, you may love seeing the behind-the scenes of our manufacturing process for OpenScope!

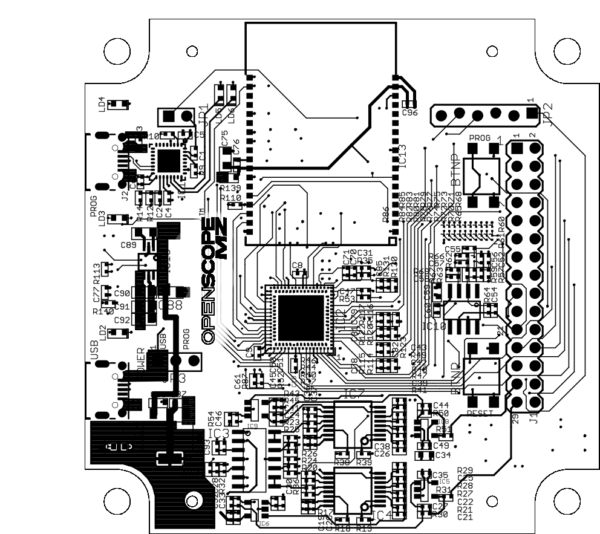

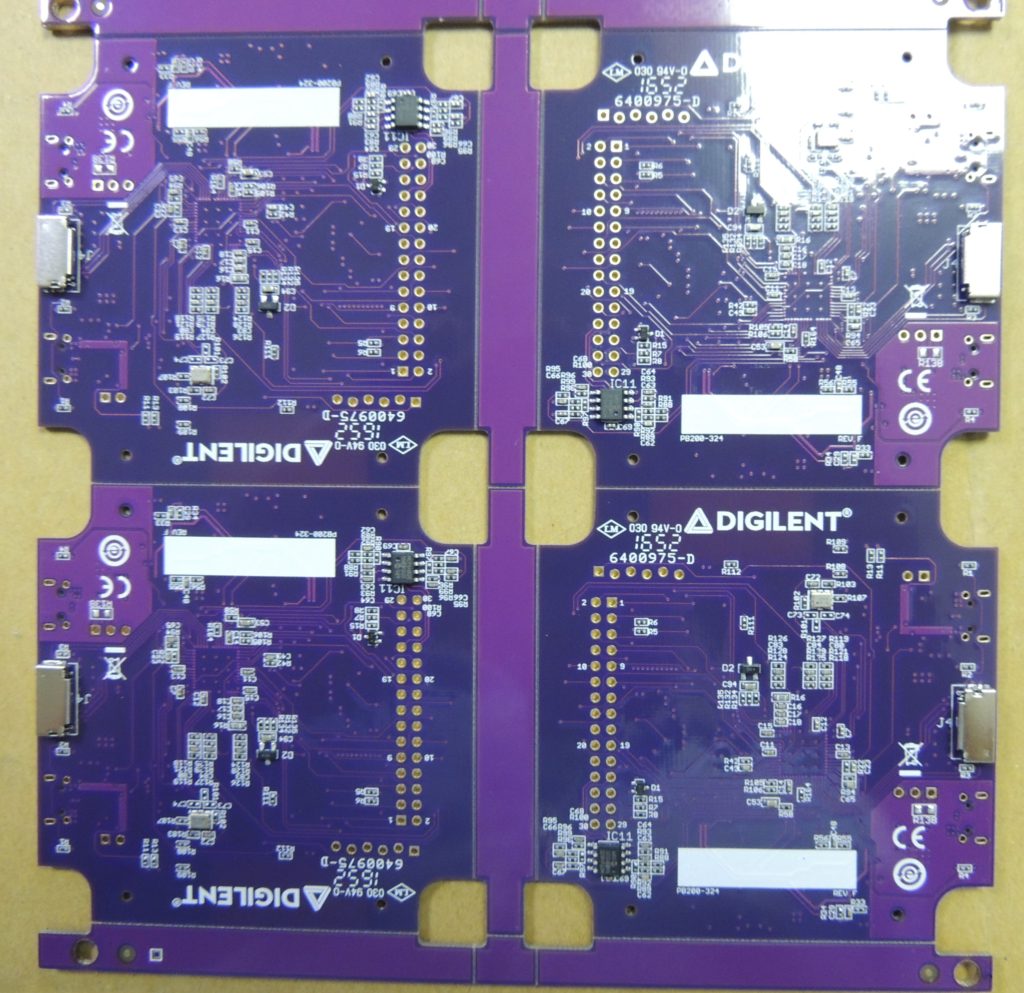

OpenScope starts life as a PCB.

Once we get it from the PCB house, it goes to manufacturing.

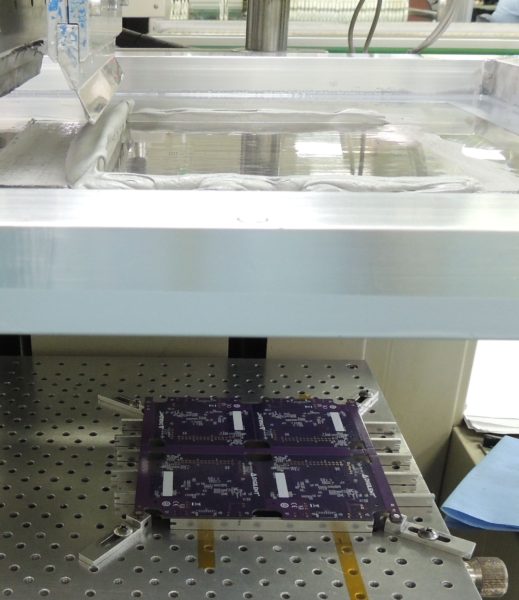

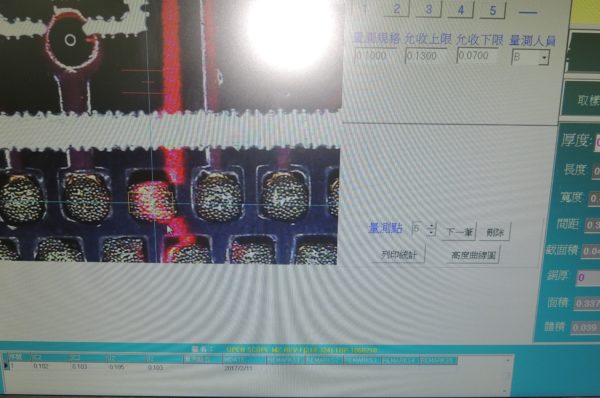

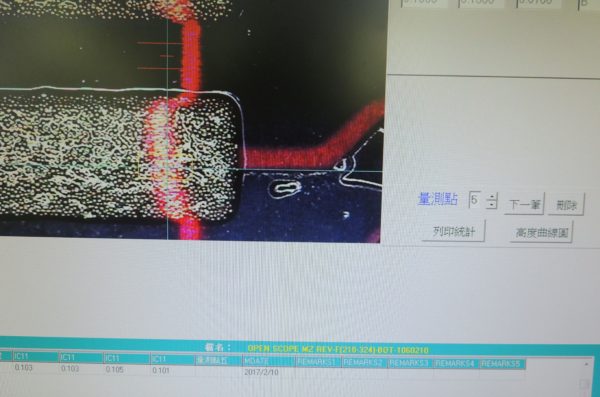

The PCB boards go and get stenciled (when the solder paste is applied uniformly, almost like a screen print).

Then, the stencil gets lifted off and sent to the pick and place machine, where parts are selected and placed over the solder paste.

It then goes to reflow (when the solder gets heated up and it grabs the part that has been placed ontop of it).

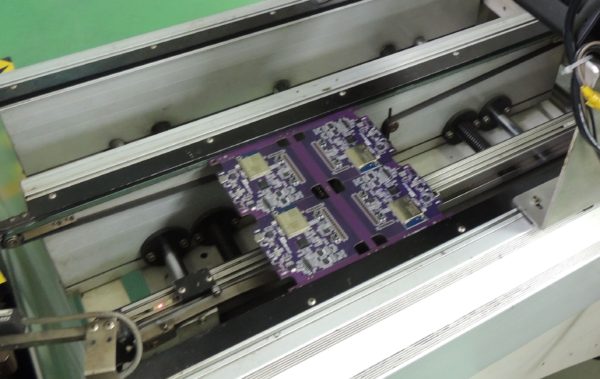

Bottom side of the OpenScope after reflow, the topside gets done next.

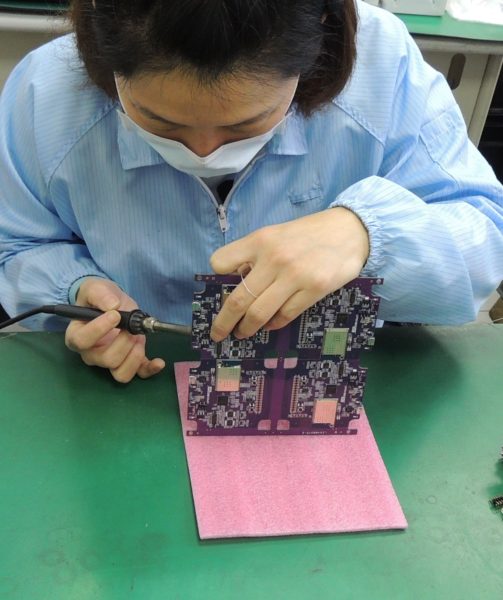

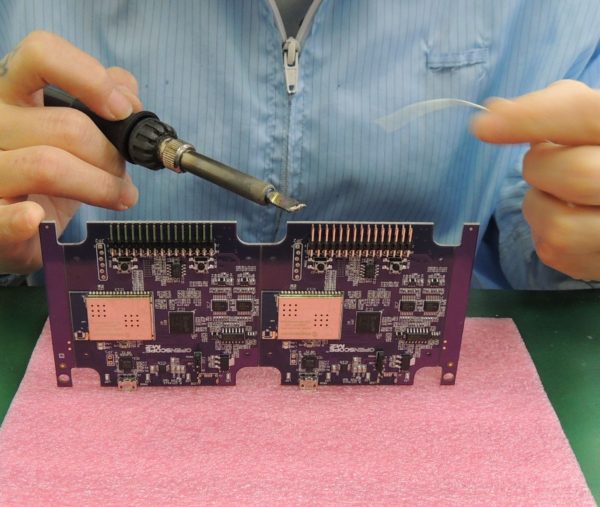

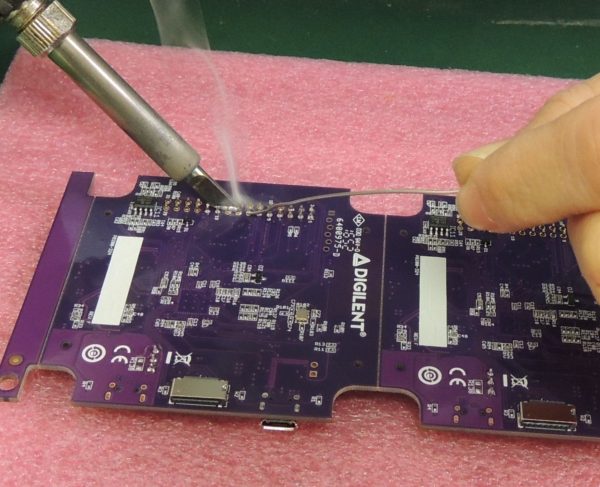

Then, the OpenScope makes it to hand soldering, these are usually things like through-hole solder pins and plastic parts (that can’t go through the oven).

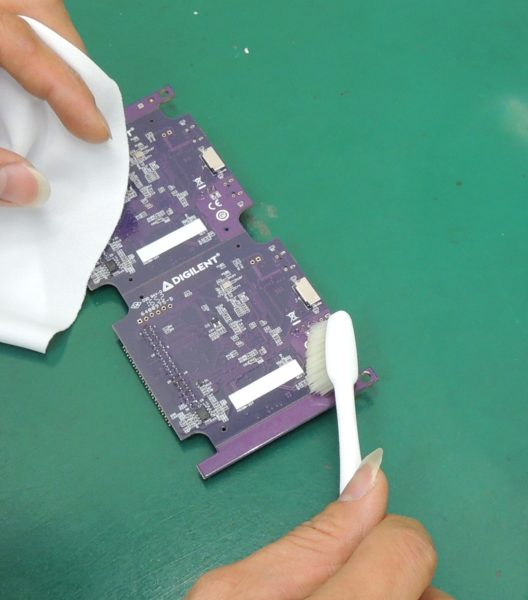

These are then cleaned off.

Cut apart…

And it is ready to go through firmware, test and then eventually packaging!

I hope you enjoyed a tour through the manufacturing process of the OpenScope!

Very cool!

Hello, thanks for the article. Where do you manufacture these?