Genesys ZU Reference Manual

TL;DR

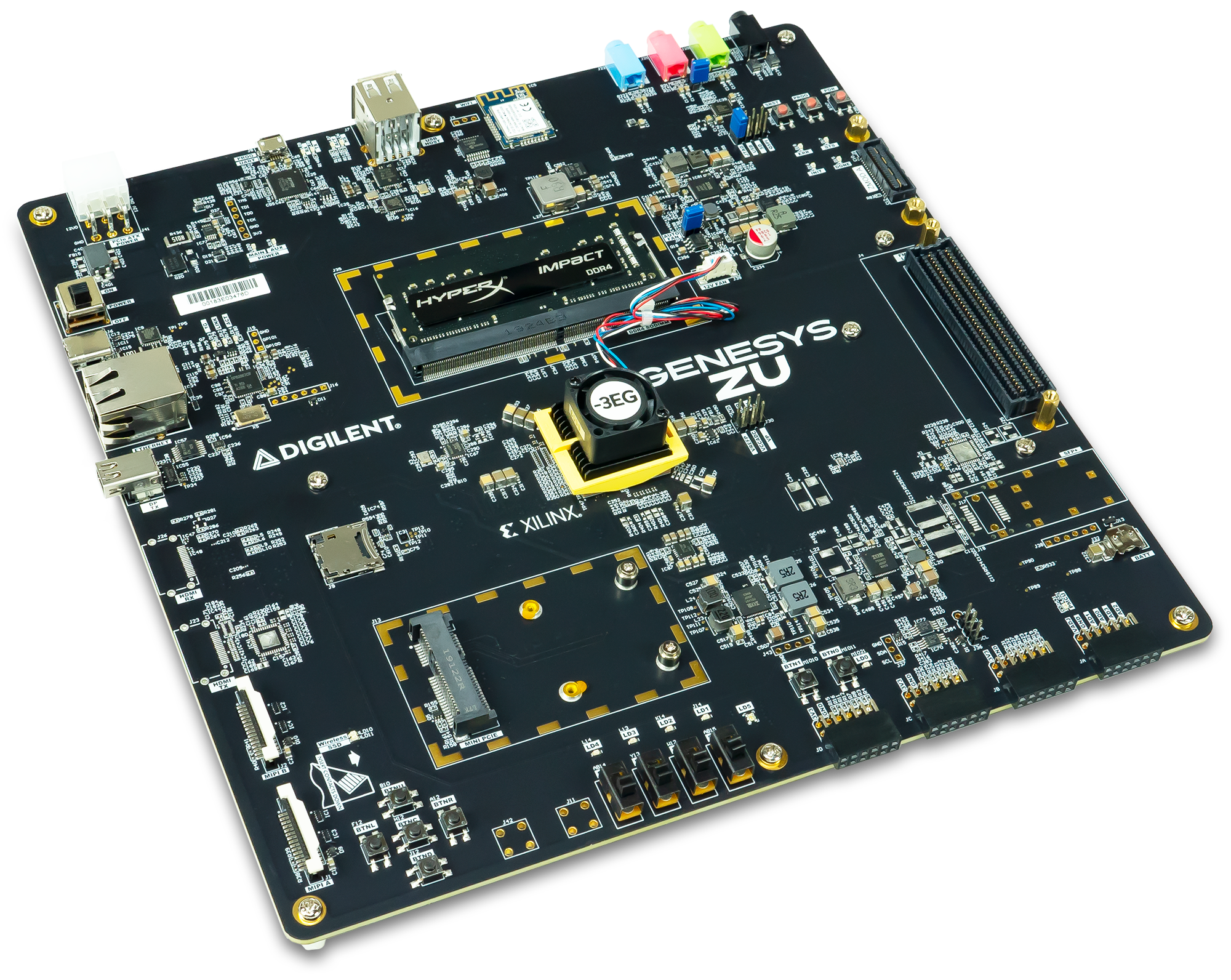

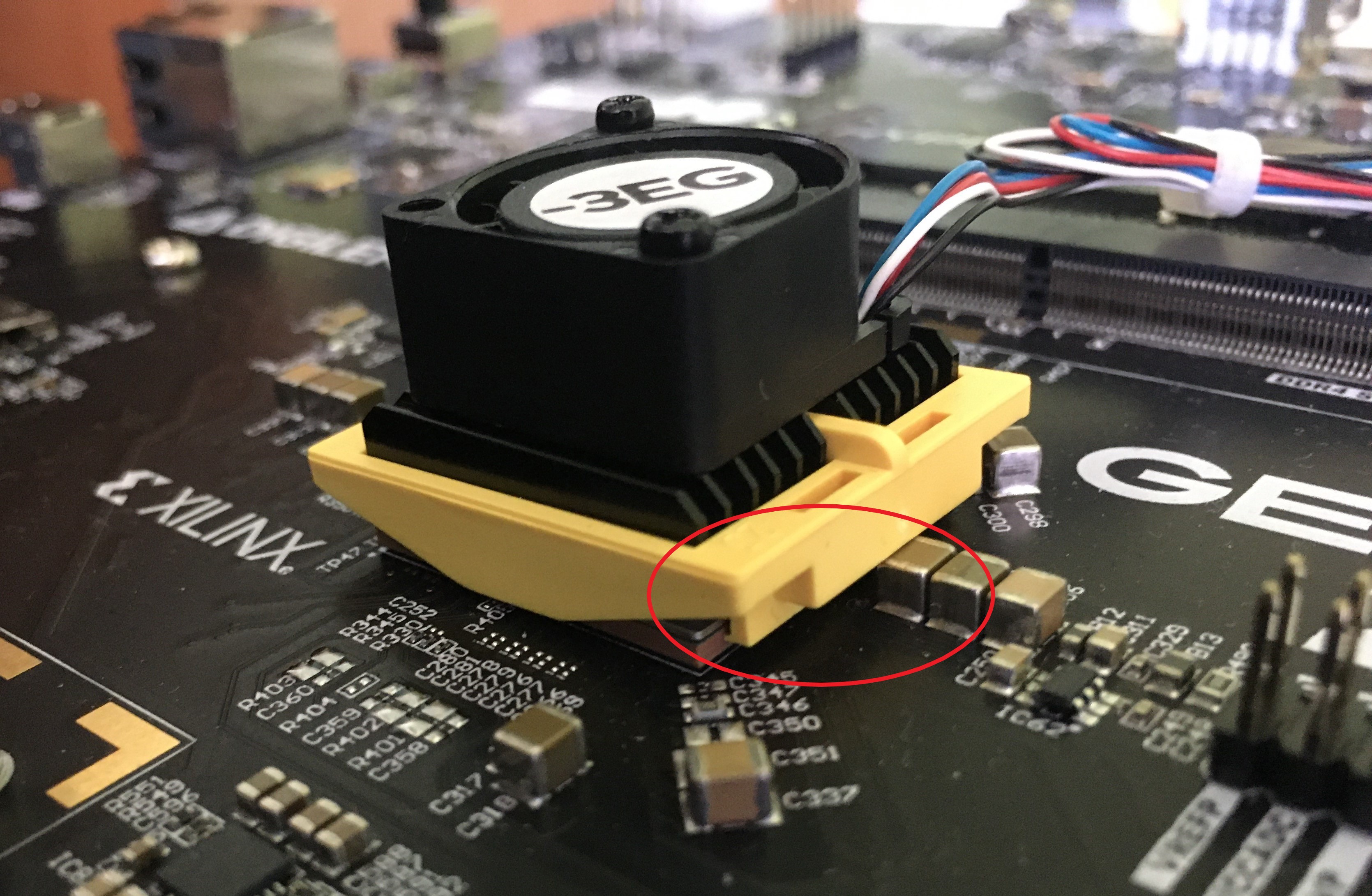

The black matte board you are holding in your hand is a prototyping and evaluation board proudly designed by Digilent. At its heart is a Xilinx Zynq UltraScale+ MPSoC ARM-FPGA hybrid, coupled with upgradeable memory, network and multimedia interfaces, and a wide variety of expansion connectors making it a versatile computing platform.

There are two variants of the Genesys ZU mentioned in this Reference Manual: 3EG and 5EV. These two variants are differentiated by the MPSoC model and some peripherals. As compared to the 3EG, with the 5EV you get slightly faster DDR4, more FPGA, a video codec, and GTH transceivers allowing HDMI Source, Sink and SFP+ 10G.

Used stand-alone with a hearty bundle in the box, powered by the 12V power supply, it straight up boots Linux from the microSD card (whoops, erratum). Connect the USB micro B cable to a PC and open a terminal (115200-8-N-1) to the first COM port out of the two that appear. Login and password are both “root”. The red button labeled “POR” always resets the MPSoC and starts the boot process again.

Want to dive deep into development? Head over to our GitHub page and use the repos there as a starting point. Check out our Getting Started Guide for a step-by-step. Build your own boot image on the SD card and boot it like the OOB demo. Not enough? Connecting the micro USB cable to header J8 will allow for on-the-fly programming and debug using Vitis or Vivado.

The Digilent Genesys ZU is a stand-alone Zynq UltraScale+ MPSoC prototyping and development board. It is an advanced computing platform with powerful multimedia and network connectivity interfaces. The excellent mix of on-board peripherals, upgrade-friendly DDR4, Mini PCIe and microSD slots, multi-camera and high-speed expansion connectors are bound to support a wide number of use-cases. Furthermore, the Genesys ZU is available in two variants with different MPSoC options and additional features for even more flexibility. Differences are highlighted* throughout this document.

The Xilinx Zynq UltraScale+ MPSoC at the heart of the Genesys ZU is a big leap from the Zynq-7000 series. Faster and more processor cores, upgraded memory interface, integrated gigabit transceivers bring support for DDR4, USB Type-C 3.1, PCIe, SATA, DisplayPort, SFP+* and HDMI*. The Genesys ZU is primarily targeted towards Linux-based applications that allows easy access to Wi-Fi, cellular radio (WWAN), SSD, USB SuperSpeed and 4K video. The bundled microSD card includes an out-of-box demo that boots a Linux image built in Petalinux and includes some test scripts for some of the peripherals.

Features

| Feature group | Sub-feature | Genesys ZU-3EG | Genesys ZU-5EV | Zedboard |

|---|---|---|---|---|

| Processor | APU | Quad A53 | Dual A9 | |

| RPU | Dual R5 | ✘ | ||

| Main Memory | DDR4, 4GB, 1866 MT/s, upgradeable | DDR4, 4GB, 2133 MT/s, upgradeable | DDR3, 512MB, 1066 MT/s, soldered | |

| GPU | ✔ | ✘ | ||

| Video Codec | ✘ | ✔ | ✘ | |

| Programmable logic | # of logic cells | 154K | 256K | 85K |

| Peripheral connectivity | USB Type-C 3.1 Gen1 Dual-Role Device | ✔ | ✘ | |

| MiniPCIe / mSATA dual slot | Half-/Full-size | ✘ | ||

| USB 2.0 Host | 2 x Type-A | 1 x OTG | ||

| Network connectivity | On-board Wi-Fi | 2.4GHz | ✘ | |

| Ethernet 1G w/ IEEE 1588 | ✔ | ✘ (w/o IEEE 1588) | ||

| WLAN / WWAN / LoRa | option - MiniPCIe | ✘ | ||

| SFP+ 10G Ethernet | ✘ | ✔ | ✘ | |

| Storage | SD | 104 MB/s | 25 MB/s | |

| SSD | option - mSATA | ✘ | ||

| Flash | ISSI 256 Mib SNOR | 128 Mib | ||

| Multimedia | DisplayPort | 1.2a Dual-Lane | ✘ | |

| Pcam | 2 x Dual-Lane | ✘ | ||

| HDMI Source | ✘ | ✔ | ✔ | |

| HDMI Sink | ✘ | ✔ | ✘ | |

| Audio Codec | ✔ | ✔ | ||

| Expansion | Low speed - Pmod | 4 x | 5 x | |

| Mid-speed - SYZYGY | ✔ | ✘ | ||

| Mid-speed - FMC | ✔ | ✔ | ||

| High-speed - FMC Gigabit | ✘ | ✔ | ✘ | |

| User I/O | LED, Buttons, Switches | ✔ | ✔ | |

- Callout with Description

-

Callout # Description Callout # Description Callout # Description 1 6-pin PCIe power connector 13 Coin battery retainer 25 Type-C USB 3.1 2 External JTAG port 14 Pmod headers 26 Power switch 3 USB JTAG/UART port 15 Dual digital/analog Pmod 27 Zynq Ultrascale+, heat sink and fan 4 USB 2.0 host connectors 16 User buttons 28 System Monitor header 5 Wi-Fi chip 17 User switches 29 SIM card slot (on the bottom side) 6 4 GiB DDR4 SODIMM module 18 Mini PCIe/mSATA slot 7 Audio jacks 19 User buttons 8 Boot mode select jumper 20 MIPI (Pcam) connectors 9 Reset buttons 21 Wireless and SSD activity LEDs 10 INIT, DONE, ERR and STS Leds 22 MicroSD Card Slot 11 Zmod (SYZYGY) connector 23 Mini DisplayPort 12 FMC LPC connector 24 1G Ethernet port

- Callout with Description

-

Callout # Description Callout # Description Callout # Description 30 SFP+ 31 HDMI Source 32 HDMI Sink

Software Support

Zynq UltraScale+ MPSoC platforms are well-suited to be embedded Linux targets, and the Genesys ZU is no exception. Digilent provides a Petalinux project that was used to build the out-of-box image.

The Genesys ZU is fully compatible with Xilinx’s high-performance Vitis™ and Vivado® suites. This tool set melds FPGA logic design and embedded ARM software development into an easy to use, intuitive design flow. It can be used for designing systems of any complexity, from a complete operating system running multiple server applications, down to a simple bare-metal program that controls some LEDs. It is also possible to treat the MPSoC as a standalone FPGA for those not interested in using the processor in their design. The two MPSoC parts the Genesys ZU is available with, XCZU3EG and XCZU5EV, are supported under Vivado ML Standard Edition (formerly Vivado WebPACK™), which means the software is completely free to use, including the Logic Analyzer and High-level Synthesis (HLS) features. The Logic Analyzer assists with debugging logic that is running in hardware, and the HLS tool allows C code to be directly compiled into HDL.

Support for board flow through board definition files is not built into Vivado 2020.1. Follow the Installing Vivado, Xilinx SDK, and Digilent Board Files guide to add that.

Initial shipments of the kit bundled a free voucher for the Xilinx MIPI CSI-2 IP cores. Starting with Vivado 2020.1 a license for these IPs is bundled with the software. See the next table for IP-support status for other peripherals.

Table I: IP support status

| Feature/Peripheral | IP support | Version |

|---|---|---|

| DDR4 memory controller | PS hard-core, WebPACK built-in | 2020.1 |

| MIPI CSI-2/Pcam | PL soft-core, MIPI CSI Controller Subsystems, bundled voucher | 2020.1 |

| DisplayPort controller | PS hard-core, WebPACK built-in | 2020.1 |

| Ethernet 1G | PS hard-core, WebPACK built-in | 2020.1 |

| USB 2.0/3.0 | PS hard-core, WebPACK built-in | 2020.1 |

| PCIe Root/Mini PCIe | PS hard-core, WebPACK built-in | 2020.1 |

| SATA/mSATA | PS hard-core, WebPACK built-in | 2019.1 |

| On-board Wi-Fi/SPI controller | PS hard-core, WebPACK built-in, open-source Linux driver | 2020.1 |

| SFP+* | PL soft-core, 10G/25G Ethernet Subsystem, PCS/PMA built-in, MAC license required | 2020.1 |

| HDMI 2.0 Source/Sink* | PL soft-core, HDMI Subsystem, license required | 2020.1 |

| Video PHY Controller* | PL soft-core, WebPACK built-in, requires protocol-implementation like the HDMI Subsystem above, supported by 5EV only | 2020.1 |

The initial Vivado/SDK/Petalinux version supported by Digilent for Genesys ZU-related projects was 2019.1. The GitHub page always holds the latest version tested and supported by Digilent. Digilent currently does not provide hardware platforms or examples for Xilinx's Vitis Unified Software Platform, however Vitis support is planned for the near future.

Design resources, example projects, and tutorials are available for download at the Genesys ZU Resource Center.

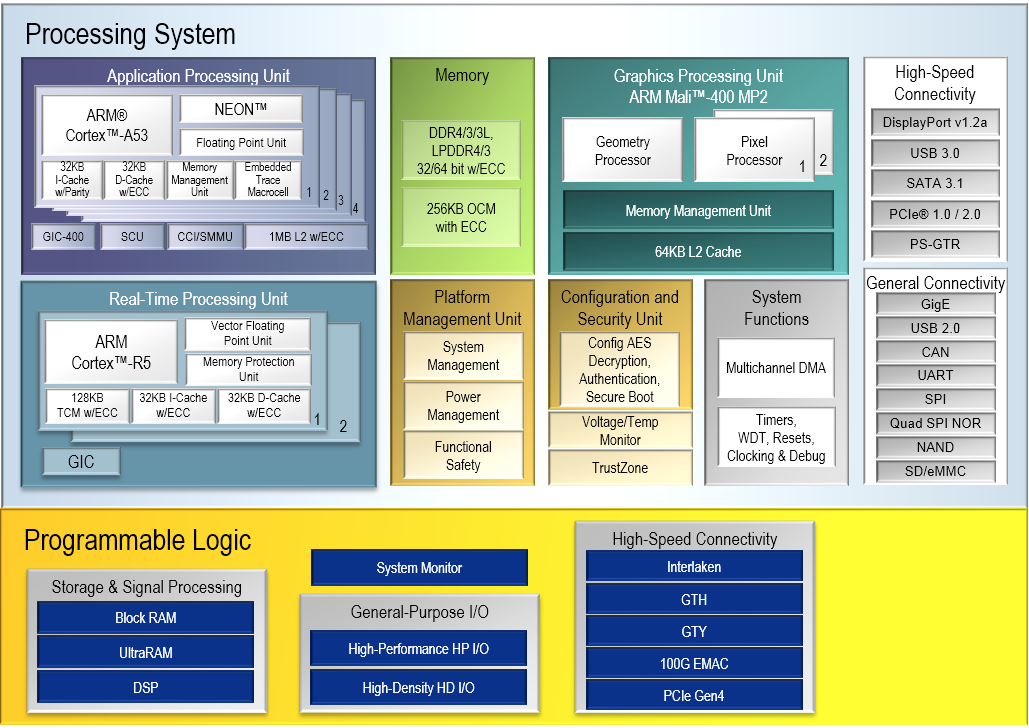

Zynq UltraScale+ MPSoC Architecture

Zynq UltraScale+ MPSoC is the Xilinx second-generation Zynq platform, combining a powerful processing system (PS) and user-programmable logic (PL) into the same device. The Zynq UltraScale+ Processing System core acts as a logic connection between the PS and the Programmable Logic (PL) while assisting you to integrate customized and integrated IP cores with the processing system using the Vivado IP integrator. As you may see in the picture below, the processing system features the Arm flagship Cortex -A53 64-bit quad-core running up to 1.5GHz and Cortex-R5 dual-core real-time processor along with other interfaces such as: DDR Memory Controller, High-Connectivity, General Connectivity, System Functions etc. The Zynq UltraScale+ MPSoC Processing System wrapper instantiates the processing system section of the Zynq UltraScale+ MPSoC for the programmable logic and external board logic. The wrapper includes unaltered connectivity with the ones presented above.

The PS and PL can be coupled with multiple interfaces and other signals to effectively integrate user-created hardware accelerators and other functions in the PL logic that are accessible to the processors. The interfaces between the processing system and programmable logic mainly consist of three main groups: the extended multiplexed I/O (EMIO), programmable logic I/O, and the AXI I/O groups. Besides those, there are up to 78 Multiplexed I/O (MIO) ports available from the processing system. The 78 MIO signals are divided into three banks, and each bank includes 26 device pins. Each bank (500, 501, and 502) has its own power pins for the hardware interface.

- MIO 0-25 : Bank 500

-

MIO 500 3.3 V Peripherals Pin QSPI Mini PCIe / SATA DDR4 SODIMM MIO Buttons WI-FI UART MIO LED I2C MUX USB 3.0 8-bit I/O Expander 0 QSPI_SCLK0OUT 1 QSPI_D1 2 QSPI_D2 3 QSPI_D3 4 QSPI_D0 5 QSPI_SS_OUTN 6(N/C) 7 PCIE_PERSTN 8 DDR_SCL 9 DDR_SDA 10 BTN1 11 BTN0 12 WIFI_PORTEX_SCK WIFI_PORTEX_SCK 13 PORTEXP_RESETN 14 PORTEX_SSN 15 WIFI_SSN 16 WIFI_PORTEX_MISO WIFI_PORTEX_MISO 17 WIFI_PORTEX_MOSI WIFI_PORTEX_MOSI 18 UART_TXD_IN 19 UART_RXD_OUT 20 PCIE_WAKEN 21 LD0 22 MUX_SCL_LS 23 MUX_SDA_LS 24 USB30_INTN 25 PORTEXP_INTN Note: The WI-FI signals are shared by the same bus that goes through the I/O expander.

- MIO 26-51 : Bank 501

-

MIO 501 1.8V Peripherals Pin Ethernet SD 26 ETH_TX_CLK 27 ETH_TX_D0 28 ETH_TX_D1 29 ETH_TX_D2 30 ETH_TX_D3 31 ETH_TX_CTL 32 ETH_RX_CLK 33 ETH_RX_D0 34 ETH_RX_D1 35 ETH_RX_D2 36 ETH_RX_D3 37 ETH_RX_CTL 38 ETH_INTN_PWDNN 39 SDIO_SEL 40 SDIO_DIR_CMD 41 SDIO_DIR_DAT0 42 SDIO_DIR_DAT1_3 43 SDIO_POW_EN 44 ETH_RSTN 45 SDIO_CDN 46 SDIO_R_DAT0 47 SDIO_R_DAT1 48 SDIO_R_DAT2 49 SDIO_R_DAT3 50 SDIO_R_CMD 51 SDIO_R_SCLK

- MIO 52-77 : Bank 502

-

MIO 502 1.8V Peripherals Pin USB 2.0 Ethernet 52 USB20_CLK 53 USB20_DIR 54 USB20_DATA2 55 USB20_NXT 56 USB20_DATA0 57 USB20_DATA1 58 USB20_STP 59 USB20_DATA3 60 USB20_DATA4 61 USB20_DATA5 62 USB20_DATA6 63 USB20_DATA7 64 USB20H_CLK 65 USB20H_DIR 66 USB20H_DATA2 67 USB20H_NXT 68 USB20H_DATA0 69 USB20H_DATA1 70 USB20H_STP 71 USB20H_DATA3 72 USB20H_DATA4 73 USB20H_DATA5 74 USB20H_DATA6 75 USB20H_DATA7 76 ETH_MDC 77 ETH_MDIO

1 Power Supplies

1.1 Power Input

The Genesys ZU power distribution network was designed to meet the specific requirements of Xilinx Zynq UltraScale+ MPSoCs and of the supported peripheral devices. Power to the board is provided via a 2×3 PCIe ATX power connector. Xilinx evaluation boards use a pinout that is not compatible with ATX, therefore mixing power supplies is not possible. The bundled supply is 12V 60W-100W, depending on variant. The board power supplies are turned on or off with the SW5 slide switch.

1.2 Power Specifications

Figure 1.2.1 gives an overview of the Genesys ZU power distribution network.

Note: The VCC0V9_MGTAVCC* and VCC0V9_VCU* rails are not used on the Genesys ZU-3EG variant.

When the board is turned on, the 12V input voltage provided by the bundled PCIe ATX supply is filtered and fed to the series MOSFETs of the protection circuit. The LM5060 IC monitors the input voltage and the current drawn by the entire board. If an input overvoltage/undervoltage or an overcurrent condition is detected, the LM5060 isolates the VCC12V0 net from the external supply by turning off the series MOSFETs.

During normal operation the MOSFETs provide a low impedance path and the VCC12V0 net is correctly biased with 12V. This voltage serves both as output rail for the FMC port and power input for downstream voltages.

Table 1.2.1 describes the list of power supply rails implemented on Genesys ZU. This table can be used to estimate the available power budget for a given project.

Table 1.2.1: Genesys ZU power rails

| Voltage Rail | Generated from | Min/Typ/Max Voltage | Max current | Used for |

|---|---|---|---|---|

| VCC12V0 | 12V power input | 12V+-5% | 8.5A | FMC, power input for other rails |

| VCC5V0_STABLE | VCC12V0 | 5V+-5% | 0.306A | IC81+IC80 , VCC3V3_STABLE |

| VCC5V0 | VCC12V0 | 5V+-5% | 4A | SYZYGY, RGB LED, Audio, USB-s, HDMI Rx AUX |

| VCC3V3_STABLE | VCC5V0_STABLE | 3.16V / 3.3V / 3.465V | 0.224A | Platform MCU, Supply I2C pull-ups, FMC, SFP, HDMI Clock, PCIe REFCLK |

| VCC3V3 | VCC12V0 | 3.154V / 3.3V / 3.4V | 7.64A | DDR4 VDDSPD (I2C interface), PCAMs, LEDs, SFP, HDMI, FMC, FPGA Internals, SYZYGY, PMODs, PCIe, SD Card, WI-FI, USB 3.0, USB 2.0 Hub, USB Config, Display Port, Flash |

| VADJ | VCC12V0 | Selectable - 1.2V / 1.5V / 1.8V +- 5% | 2.4A | FMC, SYZYGY, FPGA |

| VCC2V5 | VCC12V0 | 2.375V / 2.5V / 2.625V | 2.1A | DDR4 VPP, MGT Oscillators, Ethernet |

| VCC1V8_AUX | VCC12V0 | 1.746V / 1.8V / 1.854V | 1.59A | FPGA Internals, Ethernet, DisplayPort, Audio, USB 3.0, USB 2.0, USB Prog, SD Card |

| VCC1V8_MGT | VCC2V7_LDOIN | 1.746V / 1.8V / 1.854V | 0.09A | FPGA Internals |

| VCC1V5_PCI | VCC12V0 | 1.5V=-5% | 0.5A | PCIe port |

| VREF1V25 | VCC3V3 | 1.25V+-5% | 0.01A | XADC reference |

| VCC1V2_MGTAVTT | VCC12V0 | 1.164V / 1.2V/ 1.236V | 0.77A | FPGA Internals |

| VCC1V2_PSDDR | VCC12V0 | 1.14V / 1.2V/ 1.26V | 6.87A | FPGA Internals, DDR4 |

| VCC1V1 | VCC1V8_AUX | 1V/ 1.1V/ 1.155V | 0.49A | Ethernet, HDMI |

| VCC0V9_MGTAVCC* | VCC12V0 | 0.873V / 0.9V / 0.927V | 0.55 | FPGA Internals (5EV variant only) |

| VCC0V9_VCU* | VCC12V0 | 0.873V / 0.9V / 0.927V | 2A | FPGA Internals (5EV variant only) |

| VCC0V85_PSMGTRAVCC | VCC2V7_LDOIN | 0.825V / 0.85V /0.875V | 0.3A | FPGA Internals |

| VCC0V85_INT | VCC12V0 | 0.825V / 0.85V / 0.875V | 11A | FPGA Internals |

| VTT0V6 | VCC1V2_PSDDR | 0.6V (0.49xVCC1V2_PSDDR-0.02V… …0.51xVCC1V2_PSDDR+0.02V) | 1A | DDR4 VTT |

| VREF0V6 | VCC1V2_PSDDR | 0.6V (0.49xVCC1V2_PSDDR… …0.51xVCC1V2_PSDDR) | 0.01A | DDR4 reference voltage |

1.3 Power Sequencing

The board is powered up by sliding the SW5 switch to the ON position. The voltage supplies start-up sequence is defined by implementing a power good daisy chain that selectively enables groups of voltages that should start together. All supplies use a soft start mechanism to reduce the surge currents during turn on. The start-up sequence is suggested in Figure 1.2.1 and can be described in the following steps:

- When the ramping VCC12V0 exceeds the turn-ON threshold of IC78, the VCC5V0_STABLE rail starts up. This triggers the VCC3V3_STABLE supply and powers the IC81 internal logic. The VCC3V3_STABLE rail powers the platform MCU. Its valid state is marked by the green Aux power ON LED (LD19).

- When the protection circuit detects a valid 12V input, it asserts the INPUT_PGD signal that triggers the VCC5V0 startup. This voltage powers the internal logic of IC83 and IC84.

- If VCC5V0 reaches its power-good threshold, the PGOOD0=En1 signal is asserted. This enables the VCC0V85_INT, VCC0V9_MGTAVCC*, VCC2V7_LDOIN and VCC0V9_VCU* voltages. The power-good signals of all these supplies are joined in a wired AND configuration and activate PGOOD1 when all rails have reached their nominal voltages.

- When all voltages from the first starting group have crossed their power-good thresholds, the PGOOD1=En2 signal is asserted. This enables the VCC1V8_AUX and VCC0V85_PSMGTRAVCC voltages of the second group.

- A similar trigger mechanism applies to the third (PGOOD2=En3) and the fourth (PGOOD3=En4) voltage groups as illustrated in Figure 1.2.1. The fourth group also includes the dedicated DDR4 power supply with all its output voltages.

- If all voltages from the fourth group have succesfully reached their designed values, their power-good (PG_ALL) lights up the green Main Power ON LED (LD20). At this point the board is fully functional.

Note: the VADJ rail is controlled separately by the platform MCU that must first set VADJ depending on the peripherals using those voltage. VADJ is in the fourth start-up group but it is conditioned by a valid EN_VADJ_CTRL signal generated by the platform MCU.

Sliding the SW5 switch to the OFF position disables the power supplies by pulling INPUT_PGD to ground. The capacitor C405 connected to the EN terminal of the LM5060 monitoring IC delays the VCC12V0 turn off with approximately 200ms until all power supplies have been safely powered off.

1.4 Earthing/Grounding System

The bundled power supply has a 3-pin AC power cord and internally shorts the DC negative terminal to the earth/ground circuit of the power socket. Therefore, the Genesys ZU's ground circuits are at earth potential. In lieu of a metallic case the Genesys ZU has an internal shield ring at the edge of the board encircling it. The metallic pads of screws, feet and stand-offs (except the top right corner and Zmod stand-offs), but also the shell of connectors are wired to the shield ring. The shield ring ultimately connects to the Genesys ZU's ground circuit through a 2 mOhm resistor. There are also several capacitor pads (not loaded) around the board between the shield ring and the ground circuit. The screws on the edge of the board (except the top-right corner) can be used to wire an additional earth/ground connection to the Genesys ZU.

2 MPSoC Boot Process

2.1 JTAG Boot Mode

JTAG is the most important component of the debug features for software and PL development. The JTAG architecture has three Test Access Port (TAP) controllers:

- PS TAP (main PS controller with IDCODE)

- PL TAP (used for PL configuration and boundary scan)

- DAP (used for ARM debugging, Real time processing unit (RPU) and Application Processing Unit (APU))

Taking into account this architecture, when placed in JTAG boot mode, the processor (APU) will wait until software is loaded by a host computer using the Xilinx tools. After software has been loaded, it is possible to either let the software begin executing, or step through it line by line using Xilinx SDK.

It is also possible to directly configure the PL over JTAG, independent of the processor. This can be done using the Vivado Hardware Server.

The Genesys ZU is configured to boot in Cascaded JTAG mode, which allows the PS to be accessed via the same JTAG port as the PL.

You need a JTAG programmer to connect into the JTAG chain of the Genesys ZU. There is an on-board USB-JTAG controller with built-in support starting Vivado 2020.1. Connect the bundled USB 2.0 A-micro B cable to J8 labeled PROG/UART (no. 3 in callout diagram) and a PC. This same connection will double as a USB-UART converter too, instantiating a virtual COM port on the PC.

Up until rev B.1, the on-board USB-JTAG controller and USB-UART converter are powered from the Genesys ZU board, not from USB. This means that power-cycling the Genesys ZU board, with the USB 2.0 A-micro B cable connected from the PC to J8, will result in the UART and JTAG controller connections going away on the PC.

From rev D.1 onwards, the on-board USB-JTAG controller and USB-UART converter are powered from the PC, via their micro B USB connection; they do not share supply lines with the rest of the Genesys ZU board. This means that power-cycling the Genesys ZU board, with the USB 2.0 A-micro B cable connected from the PC to J8, will not result in the UART and JTAG controller connections going away on the PC. Also, disconnecting the USB 2.0 A-micro B cable from J8 and reconnecting it, with the Genesys ZU board powered on, will not result in the Zynq Ultrascale+ SoC getting reset; this means that a project running on the SoC will not go away as a result of this reconnection.

The JTAG chain includes the FMC connector too as required by the standard. Any JTAG device on the FMC mezzanine card is daisy-chained to the MPSoC using the TDI and TDO pins, thus extending the JTAG chain with additional devices. The standard mandates that if JTAG functionality is not used on the mezzanine card it must still loop back TDI to TDO, thus completing the chain. Some debug cards, like the Xilinx XM105, expose signals on pin headers but do not provide the loopback themselves. This will cause JTAG programmers (either on-board or external) to not detect the JTAG chain and the MPSoC anymore. When there is no mezzanine card in the FMC slot, an on-board switch loops back TDI to TDO, again completing the chain.

External programming cables can connect to the 6-pin header J28.

- Connecting to hardware in pre-2020.1 tools

-

Until built-in Vivado support became available a Digilent JTAG-HS1 or JTAG-HS2 programming cable was bundled with the kit. This cable connects to the 6-pin header J28 and is supported by pre-2020.1 Vivado versions.

Connecting both the on-board programmer and the bundled programming cable to the PC might cause conflict in Vivado Hardware Server with not the right cable being opened and no targets being found. The solution is launching Hardware Server manually before any connection attempt is made, or after killing any automatically launched instances of hw_server.exe. Launching Hardware Server manually can be done from the Vivado Tcl Shell using the command below.

Vivado% hw_server -e "set jtag-port-filter 210205,210249" WARNING: [Common 17-259] Unknown Tcl command 'hw_server -e set jtag-port-filter 210205,210249' sending command to the OS shell for execution. It is recommended to use 'exec' to send the command to the OS shell. ****** Xilinx hw_server v2019.1 **** Build date : May 24 2019 at 15:13:31 ** Copyright 1986-2019 Xilinx, Inc. All Rights Reserved. INFO: hw_server application started INFO: Use Ctrl-C to exit hw_server application INFO: To connect to this hw_server instance use url: TCP:<hostname>:3121Vivado Hardware Server is launched in the shell and will be listening until the shell is closed. All other Xilinx tools will automatically connect to this instance of the Hardware Server.

For more details about JTAG see “JTAG Functional Description” section in Zynq UltraScale+ Device Technical Reference Manual (UG1085).

2.2 microSD Boot Mode

The Genesys ZU supports booting from a microSD card inserted into the hinged connector J9. The SD supported version is 3.0. This boot mode suport FAT 16/32 file systems for reading the boot images. Image search for multi-boot is supported. For SD boot mode, the boot image file should be at the root of first partition of the SD card (not inside any directory). The following procedure will allow you to boot the Zynq UltraScale+ from microSD with a standard Zynq UltraScale+ Boot Image created with the Xilinx tools:

- Format the microSD card with a FAT32 file system.

- Copy the Zynq UltraScale+ Boot Image created with Xilinx SDK to the microSD card.

- Rename the Zynq UltraScale+ Boot Image on the microSD card to BOOT.bin.

- Eject the microSD card from your computer and insert it into connector J9 on the Genesys ZU.

- Attach a power source to the Genesys ZU.

- Place a single jumper on JP3, shorting the pins labeled “SD”.

- Turn the board on. The board will now boot the image on the microSD card.

For more details about SD boot mode see “SD Boot Mode” section in Zynq UltraScale+ MPSoC Software Developer Guide (UG1137).

2.3 Quad SPI Boot Mode

The Genesys ZU has an on-board 256Mbit Quad-SPI Flash from ISSI that the Zynq UltraScale+ can boot from. Documentation available from Xilinx describes how to use Xilinx SDK to program a Zynq UltraScale+ Boot Image into a Flash device attached to the Zynq UltraScale+. Once the Quad SPI Flash has been loaded with a Zynq UltraScale+ Boot Image, the following steps can be followed to boot from it:

- Attach a power source to the Genesys ZU.

- Place a single jumper on JP3, shorting the two center pins (labeled “QSPI”).

- Turn the board on. The board will now boot the image stored in the Quad SPI flash.

For more details about Quad SPI boot mode see “QSPI24 and QSPI32 Boot Modes” section in Zynq UltraScale+ MPSoC Software Developer Guide (UG1137).

2.4 USB Boot Mode

It is the only boot mode apart from JTAG where the MPSoC takes a slave role. It shows up as a DFU (Device Firmware Upgrade) USB device to the PC, waiting for a configuration. Using this boot mode you will be able to load the newly created image on Zynq UltraScale+ via the USB Port. For more details see the “Boot Sequence for USB Boot Mode” mode in Zynq UltraScale+ MPSoC: Embedded Design Tutorial (UG1209).

2.5 Status LEDs

The Genesys ZU has four status LEDs:

- ERR : it is asserted for accidental loss of power, a hardware error or an exception in the Platform Management Unit (PMU);

- STS : it is asserted in secure lockdown state;

- INIT : indicates the PL is initialized after the power-on reset (POR);

- DONE : it is asserted when the PL configuration is completed;

3 Main Memory

Main memory is a single-slot populated DDR4 SODIMM, always upgradeable by the user. It is wired to the PS (Processing System) side using the hard-core memory controller. The bundled module up until rev B.1 is a 4GiB Kingston HyperX HX424S14IB/4. From rev D.1 onwards the following additional modules are approved to be bundled with the Genesys ZU without advance notice to customers: Micron MTA4ATF51264HZ-2G6E1, Integral IN4V4GNEUSX, and Kingston CBD26D4S9S1KC-4. Accompanying software relies on dynamic DDR initialization code in the custom FSBL to configure the memory controller at runtime. More information can be found in AR# 75768 from Xilinx.

Although some modules support >DDR4-2400, the data rate is limited by the MPSoC and the board. The 5EV board variant supports DDR4-2133*, while the 3EG supports DDR4-1866 in single-rank configuration. In dual-rank configuration the maximum data rate falls to DDR4-1866* on the 5EV and DDR4-1600 on the 3EG.

Although the bundled module is not ECC-capable, the Genesys ZU is. Just pair it with an ECC module and enable the feature in the Vivado MPSoC PS Configuration Wizard.

3.1 Implementation

There is a single SODIMM slot on the top side of the Genesys ZU just north of the MPSoC. It is wired to the PS-side memory controller and supports any SODIMM module complying with the memory controller's restrictions. These are detailed in the Zynq UltraScale+ Device Technical Reference Manual (UG1085), but common modules of 1R/2R, x8/x16, 64b/72b are supported.

The serial presence detect (SPD) interface is wired to MIO8 (DDR_SCL) and MIO9 (DDR_SDA), accessible through the I2C1 controller.

For better routing some byte swaps were performed detailed in Table 3.1.1. No nibble or bit swaps were needed.

Table 3.1.1: DDR4 interface byte swaps.

| System | 7 | 6 | 5 | 4 | 3 | 2 | 1 | 0 | 8 |

|---|---|---|---|---|---|---|---|---|---|

| Slot | 0 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 |

ECC byte (lane 8) is equivalent to any of the data bytes from the perspective of the DRAM components. The controller and SODIMM connector have dedicated ECC pins (CBx), which are not used on non-ECC systems. Therefore the ECC lane (CBx) cannot be swapped with other lanes. However, byte and bit swaps in data lanes are transparent to the ECC feature since any swap performed upon write is reversed back upon read.

The Write CRC is a new feature of DDR4 and is complementary and unrelated to the ECC feature. Write CRC protects data in transit, ECC protects data in storage. CRC is calculated both by the controller and the DRAM to avoid data corruption in the the write data burst. It can detect single bit, double bit, odd count and one multi-bit UI vertical column errors. Upon error detection, DRAM will assert the ALERT_n line. The controller should retry the write upon error.

It should be enabled in systems that expect a high amount of signal integrity issues and where high reliability is desired. It trades data rate for reliability. CRC support is optional in SODIMM modules. Even if the module supports it, implementation is not easy. For CRC to work the controller must know what pin swaps were performed on the memory interface. In case of SODIMM modules, there are some restricted pin swaps possible and must be documented in the SPD EEPROM. The controller is expected to read these, combine it with pin swaps on the system board and assign the bits to CRC inputs accordingly. According to AR# 68788 this can be achieved through the DDRC.DQMAP registers, not well documented.

4 Storage

4.1 Quad-SPI Flash

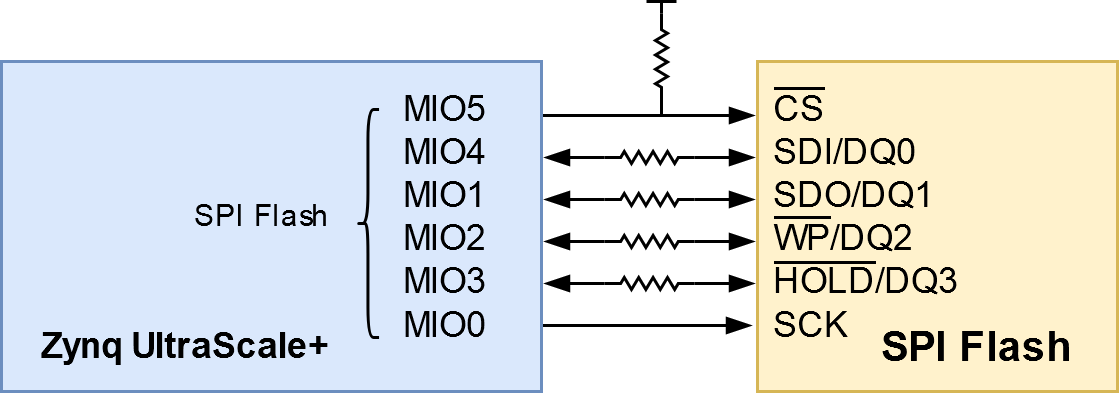

The Genesys ZU features a serial flash memory from ISSI. This memory is used to provide non-volatile code and data storage. It can be used to initialize the PS subsystem as well as configure the PL. The key device attributes are:

- Part number: IS25LP256D-JMLE

- Size: 256Mbit / 32Mbyte

- 1-bit, 2-bit and 4-bit bus widths supported

- 80MHz Normal Read, Up to 166MHz Fast Read

- Up to 664Mb/s in quad-spi mode

- Powered from 3.3V

The Flash is also commonly used to store non-configuration data needed by the application. If doing this from a bare-metal application, the flash memory can be freely accessed using standalone libraries included with a Xilinx SDK BSP project. If doing this from a Petalinux generated embedded Linux system, the Flash can be partitioned as desired and mounted/accessed like a standard MTD block device. See the Petalinux and Xilinx SDK documentation for more information.

The Flash connects to the Quad-SPI Flash controller of the Zynq UltraScale+ via pins in MIO Bank 0/500 (specifically MIO[0:5]).

The memory is divided into uniform 4 KByte sectors or uniform 32/64 Kbyte blocks. A block consists of 8/16 adjacent sectors.

Two globally unique MAC address are programmed in the last sector, sector 8191.

- MAC for Ethernet PHY is stored at address 0x1FFF000

- MAC for SFP+ (5EV only) is stored at address 0x1FFF006

The last sector, used to store the MAC addresses, is protected from write and erase. Any attempt to program or erase the last sector will fail. Consequently, blank check operations (like the one in Vivado Hardware Manager) are also expected to fail, even after a full device erase, if the last sector is not ignored.

The ISSI flash features an Advanced Sector/Block Protection mechanism. Every main flash memory array block/top sector/bottom sector has a non-volatile (PPB) protection bit associated with it. When the bit is 0, the sector is protected from program and erase operations.

There is a TBPARM bit that defines the logical location of the parameter block. The parameter block consists of thirty two 4KB sectors, which replace two 64KB blocks.

When TBPARM is set to 0 the parameter block is in the top of the memory array address space. When TBPARM is set to 1 the parameter block is at the bottom of the array. TBPARM is OTP(One-Time Programmable) and set to 1 when shipped from factory. If TBPARM is programmed to 0, an attempt to change it back to 1 will fail and ignore the program operation. For more details about the Advanced Sector/Block Protection mechanism consult the manufacturer's datasheet.

To protect the MAC addresses from the last sector, Genesys ZU comes with TBPARM programmed to 0 and the PPB bits for the last sector programmed to 0.

4.2 microSD slot

The microSD connector J9 located on the top side has a hinge-based mechanism that can be opened by sliding the housing forward, lifting the housing, and sliding the microSD card into or out of the housing shell. It is compatible with UHS-I allowing 1.8V signalling and speeds up to SDR104, or 104MB/s. To enable UHS-I support and speeds up to SDR104, see the following Answer Records from Xilinx: https://support.xilinx.com/s/article/69978 and https://support.xilinx.com/s/article/70062.

4.3 mSATA slot

The Mini PCIe connector J13 doubles as an mSATA slot allowing fast non-volatile SSD storage. Both half and full-size modules are supported. Since PCIe and SATA share the same GTR lanes, one has to disable PCIe first to enable SATA.

5 Oscillators/Clocks

The PS on Genesys ZU has a single-ended LVCMOS33 clock source of 30 MHz on pin R16 (PS_REF_CLK), coming from IC67 (5P49V6965A244NLGI), a programmable oscillator. IC67 comes pre-programmed to generate all the PS reference clocks from an 30 MHz crystal oscillator. These clocks are:

- 100 MHz HCSL33 reference clock for Mini PCIe slot,

- 100 MHz AC-coupled LVDS GTR reference clock for PCIe and USB 3.0 (PCIE_USB30_CLK_P/N = PS_MGTREFCLK0),

- 150 MHz AC-coupled LVDS GTR reference clock for SATA (SATA_CLK_P/N = PS_MGTREFCLK1),

- 108 MHz AC-coupled LVDS GTR reference clock for DisplayPort (DISPLAY_CLK_P/N = PS_MGTREFCLK2).

Although the control interface of IC67 is accessible over the I2C bus topology, there should be no need to modify the non-volatile configuration programmed during manufacturing.

The PL on Genesys ZU has a clock source of (by default) 25 MHz on pin E12 (SYSCLK), coming from the CLK_OUT pin of the Ethernet PHY IC36 (DP83867CRRGZR). This LVCMOS18 I/O standard clock can be used for any purpose in the PL, with certain restrictions:

- It enters the FPGA via HDGC (High-Density I/O Bank Global Clock) pins. These can only directly drive BUFGCE primitives, not MMCM/PLL primitives. See Global Clock Inputs in ug572. It can still drive MMCM/PLL indirectly, but this will need a CLOCK_DEDICATED_ROUTE FALSE constraint, otherwise Vivado DRC will fail.

- Is available whenever the PHY is out of reset and is not specifically configured through its registers to disable this clock. By default it is synchronous to the crystal input of the Ethernet PHY (25 MHz).

5.1 GTH Reference Clocks*

For high-speed interfaces implemented using GTH transceivers*, a user-programmable oscillator is available: IC46 (SI5342A-D-GM)*. The oscillator's only AC-coupled output drives the MGTREFCLK0 pins of GTH quad 224*. The Genesys ZU-5EV uses GTH transceivers to implement SFP+, HDMI Source, HDMI Sink, and any custom protocol over FMC GBT*.

There are two main modes this oscillator is meant to be used: free-running or jitter-cleanup. The free-running mode synthesizes a frequency suitable for the protocol implemented in the GTH quad*, using the on-board 48 MHz crystal* as reference. The jitter-cleanup mode uses one of the three differential clock inputs instead as reference: SFP_REC_CLK_P/N, FMC_MGT_CLK_P/N, and HDMI_REC_CLK_P/N. FMC_MGT_CLK_P/N is the reference clock provided by an FMC mezzanine module. The other two are provided by the FPGA on PL User I/O pins. If the FPGA outputs a clock recovered by the GTH receiver, IC46 can synchronize to it and provide a jitter-filtered reference clock of the same frequency back to the GTH quad. A typical use case would be HDMI pass-through between Sink and Source, IC46* cleaning up the received Sink clock before being used to drive the Source. More information about the oscillator modes of operation can be found here.

One of the oscillator's two one-time programmable slots is programmed during manufacturing with a free-running configuration, outputting a 156.25 MHz reference clock for 10GBASE-R applications over SFP+*. This configuration is automatically loaded upon power-up. For other clock frequencies or applications, the oscillator can be reconfigured over I2C accessible via the Main I2C Bus. It responds to address 1101000 on channel 2 of the multiplexer. For custom configurations it is recommended that the SiLabs ClockBuilder Pro design tool is used, available at https://www.silabs.com/developers/clockbuilder-pro-software. The tool is capable of exporting a register map, which can then be integrated into the user application and downloaded to the oscillator upon boot. The ClockBuilder project for the factory OTP configuration, all together with the jitter-attenuation and the free-running projects for applications over the HDMI interface can be used as starting points.

6 Reset Sources

The Genesys ZU provides several different methods of resetting the Zynq Ultrascale+ device, as described in the following sections.

6.1 Power-on Reset Signals

The Zynq Ultrascale+ PS supports external power-on reset signals. The power-on reset is the master reset of the entire chip. This signal resets every register in the device capable of being reset. The Genesys ZU drives this signal from the PG_ALL signal of the power supplies in order to hold the system in reset until all power supplies are valid. The Genesys ZU also has a red push button, labeled POR, which can toggle the power-on reset of the Zynq Ultrascale+.

6.2 Programmable Logic Reset

A red push button, labeled PROG, toggles the Zynq Ultrascale+'s PS_PROG_B input. This resets the PL and causes DONE to be de-asserted. The PL will remain unconfigured until it is reprogrammed by the processor or via JTAG.

6.3 Processor Subsystem Reset

The external system reset button, labeled SRST, resets the Zynq Ultrascale+ device without disturbing the debug environment. For example, the previous break points set by the user remain valid after system reset. Due to security concerns, system reset erases all memory content within the PS, including the On-Chip-Memory (OCM). The PL is also cleared during a system reset. System reset does not cause the boot mode strapping pins to be re-sampled. After changing boot moode jumpers a power-on reset is needed to act on the new setting.

For more details about configuration pins see “Clock, Reset, and Configuration Pins” section in Zynq UltraScale+ Device Technical Reference Manual (UG1085).

7 Network Connectivity

7.1 Wi-Fi

A Microchip ATWINC1500 module provides 2.4GHz IEEE 802.11 b/g/n wireless network connectivity. It interfaces to the MPSoC on the PS-side over SPI, supporting a maximum theoretical data rate of 48Mbps. The ATWINC1500 can be used in bare-metal applications with the full IP stack included in the firmware loaded from flash. However, it is also supported in Linux in the ATWILC1000-compatible mode, where the firmware is loaded on-the-fly upon boot and the OS IP stack is used.

7.2 1G Ethernet

The Genesys ZU uses a TI DP83867CR PHY to implement a 10/100/1000 Ethernet port for wired connectivity. The PHY connects to MIO Bank 501 (1.8V) and interfaces to the MPSoC via RGMII for data and MDIO for management. The auxiliary interrupt (ETH_INTN_PWDNN) and reset (ETH_RSTN) signals also connect to MIO Bank 501.

After power-up the PHY starts with Auto Negotiation enabled, advertising 10/100/1000 link speeds and full duplex. If there is an Ethernet-capable partner connected, the PHY automatically establishes a link with it, even with the MPSoC not configured.

Three status indicator LEDs are on-board near the RJ-45 connector that indicate speed (LD13), valid link state (LD12), and traffic activity (LD14).

Although the default power-up configuration of the PHY might be enough in most applications, the MDIO bus is available for management. The PHY is assigned the 5-bit address 01111 on the MDIO bus. With simple register read and write commands, status information can be read out or configuration changed. The TI PHY follows industry-standard register map for basic configuration.

The RGMII specification calls for the receive (RXC) and transmit clock (TXC) to be delayed relative to the data signals (RXD[0:3], RXCTL and TXD[0:3], TXCTL). Xilinx PCB guidelines also require this delay to be added. The PHY is configured to insert a delay of 2.0ns between RXD/CTL and RXC, and a delay of 1.5ns between TXD/CTL and TXC.

On an Ethernet network each node needs a unique MAC address. To this end, the last sector of the Quad-SPI flash has been programmed at the factory with a 48-bit globally unique EUI-48/64™ compatible identifier. For more details about MAC address storage see Quad-SPI Flash.

U-Boot has been patched to read this MAC address and overwrite the existing node in the device tree binary before handing control over to the Linux kernel.

The identifier is also printed on a sticker found next to the Ethernet jack (J14).

7.3 10G SFP+*

The Genesys ZU-5EV contains a single-port small form-factor pluggable (SFP+) connector J17* and shield cage J18*, compatible with SFP and SFP+ modules. It is most commonly used to implement network applications up to 10 Gbps over copper or fiber. Xilinx offers the 10G/25G Ethernet Subsystem IP to implement 10GBASE-R in the PL of the MPSoC. The IP has separate licensing for different layers of the protocol. The 10GBASE-R PCS/PMA layer requires no additional licensing and is included with Vivado. On the other hand, the 10G Ethernet MAC layer requires separate licensing.

- SFP Low-Speed Signal Connections to MPSoC XCZU5EV

-

XCZU5EV Pin Schematic Net Name I/O Standard Connected Component Pin No. Pin Name Device AA13 SFP_TX_FAULT LVCMOS33 2 TX_FAULT J17 AB13 SFP_TX_DISABLE LVCMOS33 3 TX_DISABLE J17 W14 SFP_RX_LOS LVCMOS33 8 RX_LOS J17 W13 SFP_RS0 LVCMOS33 7 RS0 J17 Y14 SFP_RS1 LVCMOS33 9 RS1 J17 AD14 SFP_MOD_DETECT LVCMOS33 6 MOD_ABS J17

All the low-speed signals in the table above are pulled up by on-board resistors. This is especially important in the case of TX_DISABLE, which must be actively driven low for the SFP(+) module to enable its transmitter.

The I2C bus of the SFP+ slot connects to the Main I2C Bus of the board on branch 6 of the I2C multiplexer.

The high-speed transmitter and receiver lanes connect to channel 3 of GTH Quad 224* through a high-speed multiplexer. Since SFP+, FMC Gigabit and HDMI Source/Sink share the same GTH Quad, it is up to the IP implementations to properly share the Quad primitives amongst themselves. For example, HDMI Subsystem can implement both HDMI Source and Sink simultaneously, but does not have sharing options with the Ethernet Subsystem, even though SFP+ is on a separate GTH Channel.

Therefore, the SFP+*, FMC Gigabit* and HDMI* features cannot be used simultaneously on the Genesys ZU-5EV.

7.3.1 High-Speed Multiplexer*

Channel 3 of GTH Quad 224* is shared between FMC LPC gigabit data pairs DP0_M2C_P/N and DP0_C2M_P/N, and SFP+ high-speed data pairs TD and RD through a CBTU02043 high-speed multiplexer IC38*. Therefore, the SFP+ slot and the FMC gigabit features cannot be used simultaneously. The multiplexer is controlled by the User I/O signal SEL_SFP_NOT_FMC on pin D10 of the MPSoC PL, as seen below.

Table 7.3.1.1: High-speed multiplexer control

| SEL_SFP_NOT_FMC | Enabled feature |

|---|---|

| Low (default) | FMC gigabit |

| High | SFP+ |

7.3.2 Reference Clock*

GTH Quad 224* has two reference clock inputs, one of which is dedicated to HDMI Sink* (MGTREFCLK1P/N). The other (MGTREFCLK0P/N) is generated by a Silicon Labs Si5342A-D-GM IC46* and can be used for networking applications. This oscillator outputs a free-running 156.25 MHz reference clock by default.

Clock recovery can also be used, where the clock received from the SFP(+) module is filtered by oscillator IC46* before being used as reference in the GTH transceiver. Refer to section GTH Reference Clocks for more information.

7.4 WLAN, Bluetooth, WWAN

The Mini PCIe socket allows you to connect any wireless radio module compatible with the PCIe Mini Card standard. With both PCIe x1 and USB 2.0 available in the socket, even dual Wi-Fi/Bluetooth modules can be used. The primary use case is Linux OS, so modules with Linux drivers available in-kernel are recommended. For WWAN radio modules a SIM slot is present on the bottom side of the board.

8 Peripheral Connectivity

8.1 USB Full-Featured Type-C

USB 3.1 Gen1 and USB 2.0 support is handled by the Full-Featured Type-C receptacle J6. The connector has a USB 2.0 pair for backward compatibility, one high-speed transceiver lane (two pairs) for USB 3.1, and configuration channel (CC). Since the plug is reversible, the upper and lower rows double the number of pins for each function, designated by suffixes 1 and 2. Plug orientation is established during the configuration process over the CC1 and CC2 pins. Depending on the orientation, either pins with suffix 1 or pins with suffix 2 carry actual signals. Multiplexing 1 and 2 for the USB 3.1 lane is done by an on-board hardware multiplexer.

Unlike the other USB connector types, Type-C does not inherently establish the relationship of host and device ports. This relationship is determined during the same configuration process.

On the Genesys ZU, data behavior is Dual-Role-Data (DRD), ie. can behave either as a Downstream-Facing Port (DFP) or an Upstream-Facing Port (UFP), depending on the connected partner and MPSoC configuration. Power behavior is Dual-Role-Power (DRP), but even if UFP is negotiated, the board remains self-powered. In DFP role the advertised current capability and limit is 0.9 A with the possibility of increasing it to 1.5 A. USB Power Delivery is not supported.

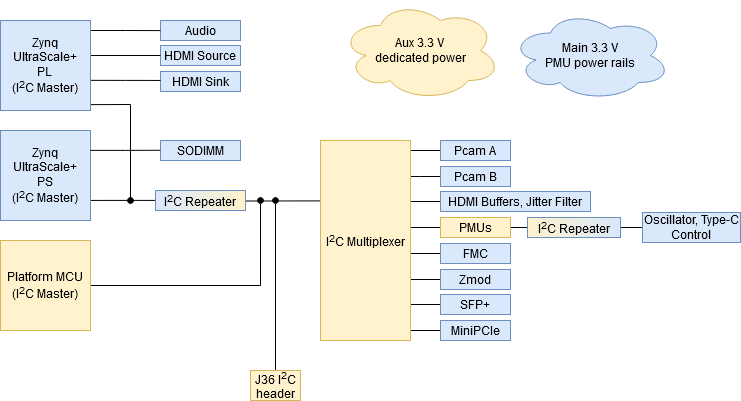

Management of the Type-C port is handled by a companion chip, the TI TUSB322I. It handles attachment, cable orientation, role detection and current advertisment. It connects to the main I2C bus of the board and can be used to read status and set port roles for Type-C. It responds to address 1000111b on branch 3 of the I2C multiplexer.

The USB 2.0 pair is implemented by a Microchip USB3320 PHY interfacing with the PS-side controller of MPSoC over ULPI. The USB 3.1 lane is implemented using a PS-GTR transceiver lane.

In the box you can find a USB Type-C Legacy Adapter reference as CAR3G1-3 in the Type-C specifications. It has a Full-Featured Type-C plug on one end and a USB 3.1 Standard-A receptacle on the other. Use it to connect non-Type-C USB 2.0 or USB 3.1 devices to the Genesys ZU.

8.2 USB 2.0 Host

Host-only USB 2.0 functionality is implemented by a Microchip USB3320 PHY and a Microchip USB2513B hub. The PHY is wired to the PS-side controller of MPSoC over ULPI. The hub has three Downstream-Facing Ports. Two of these connect to a dual-stacked Type-A connector, providing 0.5A current per port. The third port is connected to the MiniPCIe slot, an embedded USB port. This allows interfacing with Bluetooth modules, for example.

8.3 USB 2.0 - JTAG/Serial Bridge

The micro Type-B connector J8 connects to an FTDI FT4232HQ USB bridge. It provides a JTAG interface for programming and debugging, one UART interface connected to the MPSoC and one UART interface connected to the Platform MCU. The UART interfaces are exposed as standard COM ports. Their exact designator is determined upon enumeration, but the first one will always connect to the MPSoC and the second one to the Platform MCU. The MPSoC UART interface is wired to the PS-side MIO Bank 500: UART_TXD_IN to MIO18 and UART_RXD_OUT to MIO19. Signal names that imply direction are from the point-of-view of the DTE (Data Terminal Equipment), in this case the PC (e.g. UART_TXD_IN is the TXD signal of the DTE, meaning it is an output of the DTE and an input of the DCE). The Digilent USB-JTAG function and the USB-UART functions behave independent of one another. Support for USB-JTAG in Vivado is expected in version 2020.1. Read more in section JTAG Boot Mode.

9 Multimedia

9.1 DisplayPort Source

The dual-lane mini DisplayPort connector J27 is wired to a PS-side DisplayPort Controller via two PS-GTR transceiver lanes. Resolutions up to 4Kx2K@30fps are supported at a maximum 5.4Gbps line rate. It is not a dual-mode DisplayPort (DP++) port, therefore passive mini-DP to DVI/HDMI adaptors will not work. Connect it to a DisplayPort monitor with a mini-DP to DP cable, if necessary.

The DisplayPort Auxiliary interface is wired to PL-side pins, therefore routed through EMIO. The EMIO port dp_aux_data_oe_n needs to be inverted to fit the active-high polarity of the DP_AUX_DOE signal on the Genesys ZU. This can easily be done in PL logic and our https://github.com/Digilent/Genesys-ZU-OOB-hw repo shows how to do it.

9.2 HDMI Source*

The PL side of the Genesys ZU-5EV ZynqUltrascale+ can forward the incoming video and audio streams to the PHY layer via HDMI 1.4/2.0 Transmitter Subsystem from Xilinx. The subsystem bundles a collection of HDMI TX-related IP sub-cores and outputs them as a single IP, providing an out-of-the-box ready-to-use HMDI system. For better performance and quality, the subsystem can be configured through the Vivado®Integrated Design Environment (IDE).

The Genesys ZU-5EV board provides a High-Definition Multimedia Interface (HDMI™)* video output using a TI SN65DP159RGZR HDMI retimer at IC41*, on a receptacle at J23. This device is a dual-mode DisplayPort to transition-minimized differential signal (TMDS) retimer supporting digital video interface (DVI) 1.0 and HDMI 1.4b and 2.0 output signals. The device supports data rates up to 6 Gb/s per data lane to support Ultra HD (4K x 2K / 60 Hz) 8-bits per color high-resolution video and HDTV with 16-bit color depth at 1080p (1920 x 1080 / 60 Hz). A convenient characteristic is its ability to automatically configure itself as a redriver at data rates <1 Gb/s, or as a retimer at more than this data rate. This feature can be turned off through I2C programming. The SN65DP159RGZR HDMI retimer data inputs are wired to GTH Quad 224*. The necessary logic for properly interfacing the HDMI Tx Subsystem media access control and the serial transceiver is incorporated by the Video PHY Controller IP from Xilinx. The core enables simple connectivity for each TX path, together with some domain-specific configurability. The HDMI video transmit and receive block diagram is shown below, where the Video Phy Controller and the HDMI Transmit Subsystem are bundled as IP-sub cores by the HDMI Subsystem.

The connections between the codec and the XCZU5EV MPSoC are listed bellow.

- HDMI Block Interface Connections to MPSoC XCZU5EV

-

XCZU5EV Pin Schematic Net Name I/O Standard Connected Component Pin No. Pin Name Device U4 HDMI_TX_D1_C_P MGT (I/O Standard do not apply) 8 IN_D0p/IN_D1p SN65DP159 (IC41) U3 HDMI_TX_D1_C_N MGT (I/O Standard do not apply) 9 IN_D0n/IN_D1n W4 HDMI_TX_D0_C_P MGT (I/O Standard do not apply) 5 IN_D1p/IN_D0p W3 HDMI_TX_D0_C_N MGT (I/O Standard do not apply) 6 IN_D1n/IN_D0n R4 HDMI_TX_D2_C_P MGT (I/O Standard do not apply) 11 IN_CLKp/IN_D2p R3 HDMI_TX_D2_C_N MGT (I/O Standard do not apply) 12 IN_CLKn/IN_D2n C1 HDMI_TX_CLK_C_P DIFF_HSTL_I_DCI_12 2 IN_D2p/IN_CLKp B1 HDMI_TX_CLK_C_N DIFF_HSTL_I_DCI_12 3 IN_D2n/IN_CLKn H14 HDMI_TX_SCL_SRC LVCMOS33 46 SCL_SRC H13 HDMI_TX_SDA_SRC LVCMOS33 47 SDA_SRC G3 HDMI_TX_OE LVCMOS12 42 OE G15 MUX_SCL_LS LVCMOS33 15 SCL_CTL G14 MUX_SDA_LS LVCMOS33 16 SDA_CTL F11 HDMI_RX_SCL_LS LVCMOS18 2 SCLA PCA9517ADP (IC52) E10 HDMI_RX_SDA_LS LVCMOS18 3 SDAA G11 HDMI_CEC LVCMOS18 24 CEC_A TPD12S016RKTR (IC44) F10 HDMI_TX_HPD LVCMOS18 3 HPD_A D6 CLKGTH_LOLN_LS LVCMOS12 27 LOLb Si5342A-D-GM (IC46) G8 CLKGTH_RST LVCMOS12 17 RSTb C4 CLKGTH_INTRN_LS LVCMOS12 33 INTRb C3 HDMI_REC_CLK_P DIFF_HSTL_I_DCI_12 10 IN2 C2 HDMI_REC_CLK_N DIFF_HSTL_I_DCI_12 11 IN2b Y6 FMC_SFP_HDMI_TX_CLK_C_P MGT (I/O Standard do not apply) 20 OUT0 Y5 FMC_SFP_HDMI_TX_CLK_C_N MGT (I/O Standard do not apply) 19 OUT0B Y2 HDMI_RX_D0_C_P MGT (I/O Standard do not apply) 29 OUT_D0p TMDS181IRGZT (IC49) Y1 HDMI_RX_D0_C_N MGT (I/O Standard do not apply) 28 OUT_D0n V2 HDMI_RX_D1_C_P MGT (I/O Standard do not apply) 32 OUT_D1p V1 HDMI_RX_D1_C_N MGT (I/O Standard do not apply) 31 OUT_D1n T2 HDMI_RX_D2_C_P MGT (I/O Standard do not apply) 35 OUT_D2p T1 HDMI_RX_D2_C_N MGT (I/O Standard do not apply) 34 OUT_D2n V6 HDMI_RX_CLK_C_P MGT (I/O Standard do not apply) 26 OUT_CLKp V5 HDMI_RX_CLK_C_N MGT (I/O Standard do not apply) 25 OUT_CLKn F3 HDMI_RX_HPD LVCMOS12 33 HPD_SNK

9.3 HDMI Sink*

The received video and audio streams can be decoded and properly interfaced with PHY layers via HDMI 1.4/2.0 Receiver Subsystem on the PL side of the Genesys ZU-5EV ZynqUltrascale+. The subsystem is a soft IP incorporating all the necessary functionalities through a collection of HDMI RX-related IP sub-cores. For better performance and quality, the subsystem can be configured through Vivado®Integrated Design Environment (IDE). The Genesys ZU-5EV board accepts HDMI video input on the 19 pin edge connector with shield at J26*. All the TMDS RX signals are connected to TMDS181IRGZT retimer*. This device supports four TMDS channels, an audio return channel, and digital control interfaces together with signaling rates up to 6 Gbps to allow for the highest resolutions of 4k2k60p24 bits per pixel and up to WUXGA16-bit color depth or 1080p with higher refresh rates. It will automatically configure itself as a redriver at lower data rates (<1.0 Gbps) or as a retimer above this data rate. In redriver mode, the device supports HDMI1.4b with data rates up to 3.4 Gbps. More details about the supported resolutions and color spaces can be found by accessing the HDMI Subsystem documentation. The TMDS181IRGZT retimer/redriver outputs are wired to GTH Quad 224*. Same as for the TX path, the connectivity with the serial transceivers is made by the Video PHY Controller. Thus, the Video PHY Controller IP is not intended to be used as a stand-alone IP. To understand the behavior, use, and any limitations of the transceivers, please see UltraScale Architecture GTH Transceivers User Guide (UG576).

9.4 HDMI Clock Recovery*

The Genesys ZU-5EV board includes a Silicon Labs Si5342A-D-GM jitter attenuator IC46*, with output frequency ranges from 100 Hz to 1028 MHz for differential and 100 HZ to 250 MHz for LVCMOS. The FPGA can output the RX recovered clock to a differential I/O pair on I/O bank 66 HDMI_REC_CLK_P (pin C3) and HDMI_REC_CLK_N (pin C2) for jitter attenuation. The jitter attenuated clock (FMC_SFP_HDMI_TX_CLK_C_P and FMC_SFP_HDMI_TX_CLK_C_N) is then routed as a reference clock to MGT Bank 224 inputs Y6 and Y5*. Genesys ZU-5EV HDMI Demo project uses the Si5342A-D-GM jitter attenuator for generating the reference clock for the HDMI Transmitter Subsystem. When in standalone mode, the Si5342A-D-GM operates in free-running mode and uses the X1 48 MHz external oscillator* as a reference. When the HDMI is in pass-through mode, the Si5342A-D-GM generates a jitter-attenuated reference clock to drive the HDMI Transmitter Subsystem with a phase-aligned version of the HDMI RX Subsystem HDMI RX TMDS Clock. The configuration and operation of the device are controlled by reading and writing registers over the I2C bus topology, on channel 2 of the TCA9548A device. The Si5342A-D-GM I2C device address is 0b1101000.

9.5 Audio Codec

The Genesys ZU board includes an Analog Devices ADAU1761 SigmaDSP audio codec (IC39) complementing its multimedia features. Four 1/8” (3.5mm) audio jacks are available for line-out (J20-green), headphone-out (J19-black), line-in (J22-blue), and microphone-in (J21-pink). Each jack carries two channels of analog audio (stereo), with the exception of the microphone input, which is mono.

To record or play back audio the audio data needs to be converted. The audio codec bridges the gap between the analog jacks and the digital FPGA pins. It connects to the PL side of the MPSoC. Analog-to-digital and digital-to-analog conversion is done at up to 24 bits and 96 kHz sampling rate. Digital audio data is carried to/from the FPGA on a serial, full-duplex interface, which supports several different formats, the default being I2S. This interface is clocked by the FPGA through BCLK by default, but the codec can be configured to provide the clock itself.

Configuring the audio codec can be done over I2C. It responds to slave address 0b0111011 on a dedicated I2C bus, followed by a 16-bit register address and one or more data bytes. These registers control every functional aspect of the codec.

The codec is clocked from the FPGA through the Master Clock (MCLK) pin. A clock must be provided for the codec to function, including the I2C port. The exact frequency depends on the desired sample rate and whether PLL will be used, but 12 MHz is a good start.

For proper use, the concept of audio paths needs to be understood. Internal to the codec there are two signal paths: Playback and Record. Both are highly configurable analog paths with mixers and amplifiers that route audio signals through the chip. The Playback path is the output path that routes audio from different sources like the digital-to-analog converter or input mixers towards the headphone and line out jacks. On the other hand, the record path routes audio from the line-in and microphone-in towards the analog-to-digital converters. Having routing elements at every step enables signal mixing between channels, amplification, muting and bypass. However, it also means that each element has to be properly configured along the path.

Keep in mind that audio jack designations might differ from codec analog frontend designators. For example, the line-in jack connects to the AUX port of the codec. The microphone jack is wired to the IN port. Also, notice that although some ports offer differential amplifiers and signaling, they are not used on the Genesys ZU. For example, the OUT port is differential, comprising 4 pins: LOUTP, LOUTN, ROUTP, and ROUTN. However, the N-side of the differential pairs is left floating, while the P-side connects to the jack.

At the very least an audio-aware FPGA design should do the following:

- Provide MCLK for the audio codec.

- Use an I2C master controller to configure the core clocking, sample rates, serial interface format and audio path.

- Send or receive audio samples over the serial audio data channel for playback or record.

More advanced users might want to try additional features of the ADAU1761. For example, the on-chip SigmaDSP core can be programmed to do user-defined digital signal processing.

All relevant information can be found in the ADAU1761 datasheet.

9.6 MIPI/Pcam Ports

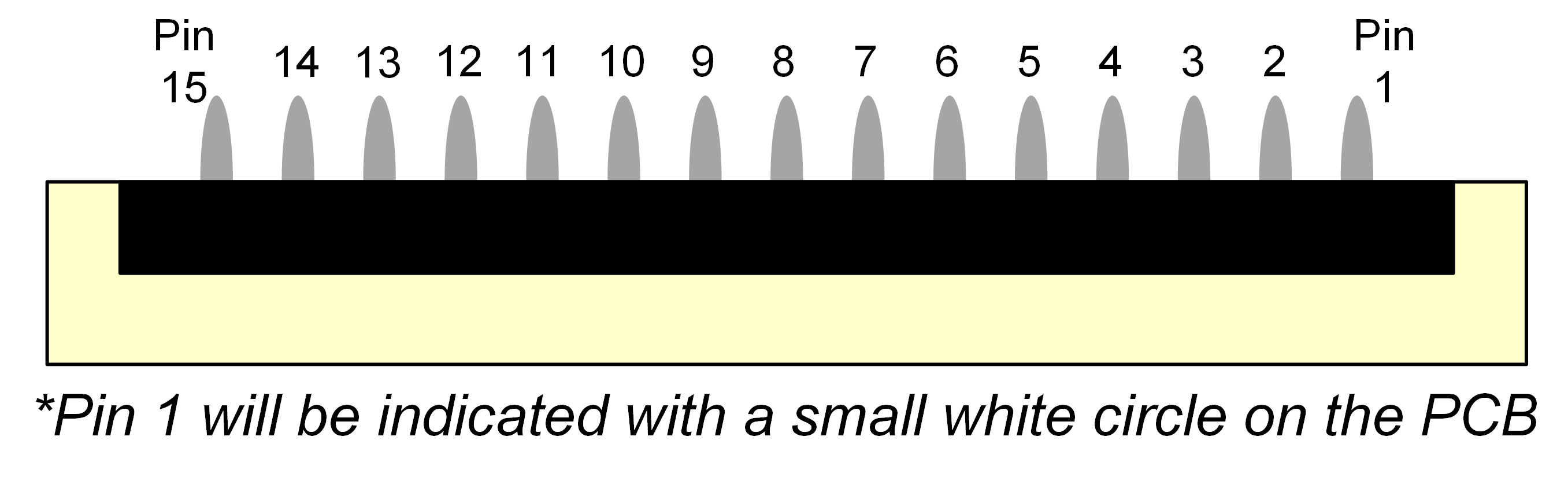

The two MIPI/Pcam ports included on the Genesys ZU are 15-pin, 1 mm pitch, zero insertion force (ZIF) connectors designed specifically for attaching camera sensor modules to host systems. It builds on the Pcam connector standard introduced on the Digilent Zybo Z7, but allows for bi-directional D-PHY lanes thanks to direct I/O support in the UltraScale+ architecture. Therefore, it supports MIPI DSI applications too, while remaining backward compatible with MIPI CSI-2 Pcam modules, like the Digilent Pcam 5C.

The Pcam connector pin-out is rigidly defined and includes a two lane MIPI CSI-2 bus for camera data, an I2C bus for camera configuration, two additional general purpose signals, and 3.3 V for powering the camera module, as depicted in Figure 9.6.1 and Table 9.6.1. Digilent is developing a catalog of Pcam peripheral camera modules with various different types of sensors that all conform to this pin-out. The pin-out was also chosen so that many camera modules designed to work with the Raspberry Pi will also work when connected to the Pcam port.

Table 9.6.1: Pcam Pin-out

| Pin Number | Function | Genesys ZU Implementation |

|---|---|---|

| 1 | GND | GND |

| 2 | MIPI D-PHY Lane 0 (-) | Connected to a 1.2V VCCO HP bank |

| 3 | MIPI D-PHY Lane 0 (+) | Connected to a 1.2V VCCO HP bank |

| 4 | GND | GND |

| 5 | MIPI D-PHY Lane 1 (-) | Connected to a 1.2V VCCO HP bank |

| 6 | MIPI D-PHY Lane 1 (+) | Connected to a 1.2V VCCO HP bank |

| 7 | GND | GND |

| 8 | MIPI D-PHY Clock (-) | Connected to a 1.2V VCCO HP bank |

| 9 | MIPI D-PHY Clock (+) | Connected to a 1.2V VCCO HP bank |

| 10 | GND | GND |

| 11 | GPIO/Power enable | Connected to a 1.2V VCCO HP bank via a 3.3V level-translator |

| 12 | GPIO/Clock feedback | N/C |

| 13 | SCL | Connects to branch 0 (MIPI A) and branch 1 (MIPI B) of the main I2C bus multiplexer |

| 14 | SDA | Connects to branch 0 (MIPI A) and branch 1 (MIPI B) of the main I2C bus multiplexer |

| 15 | 3V3 | 3.3 V Power rail |

Pcam modules are connected to the Pcam host port using a flexible flat cable (FFC). To connect the cable to the Genesys ZU follow these instructions:

- Locate the Pcam connector.

- Pull directly up on the white colored tab to open the connector.

- Insert the FFC with the contacts facing the left edge, away from the center of the Genesys ZU.

- Ensure the FFC is fully inserted.

- Gently press down on both sides of the white colored tab to latch the FFC into the connector.

- The FFC is now connected properly.

9.6.1 Routed Lengths

Each port was routed with maximum 10 ps inter-lane mismatch (~1.4 mm) on the Genesys ZU, which is half the allowed mismatch for 1000 Mbps data rate or UI_INST,MIN=1 ns. The other half is reserved for the interconnect and Pcam. The exact trace lengths can be seen in Table 9.6.1.1 below.

- Table 9.6.1.1: PCB Trace Lengths of MIPI/Pcam Nets

-

Net Name Routed Length (mm) MIPI_A_CLK_N 147.365 MIPI_A_CLK_P 147.29 MIPI_A_LANE0_N 146.496 MIPI_A_LANE0_P 146.447 MIPI_A_LANE1_N 147.107 MIPI_A_LANE1_P 147.026 MIPI_B_CLK_N 119.39 MIPI_B_CLK_P 119.292 MIPI_B_LANE0_N 120.396 MIPI_B_LANE0_P 120.329 MIPI_B_LANE1_N 119.478 MIPI_B_LANE1_P 119.461

9.6.2 Simulation Models

S-parameter models for MIPI D-PHY nets can be downloaded from here. The modeled transmission line includes the PCB traces only.

10 Expansion Ports

10.1 Mini PCIe / mSATA

J13 socket implements a versatile expansion option for adding SSD, WLAN, Bluetooth or WWAN modules to the Genesys ZU. It is compatible with PCI Express Mini card types F1/F2 (Full-Mini) and H1/H2 (Half-Mini) and mSATA card types Mini and Full size. Mechanical compatibility is assured by the relocatable stand-offs included with the board. Electrically, the SATA lane and the PCIe x1 lane share the same PS-GTR transceiver lane. Therefore, it is up to the MPSoC configuration to enable either the SATA or the PCIe Root controller and map it to the GTR lane. The SATA controller in the MpSoC supports transfer rates up to 6 Gb/s, while the PCIe Controller up to Gen2 or 5 Gb/s. Both protocols use 8b/10b encoding, so the theoretical maximum data rate is 600MB/s for SATA and 500MB/s for PCIe.

Mini PCIe modules can also make use of the embedded USB 2.0 port wired to the on-board USB hub and the MPSoC USB1 controller up the chain.

Since some modules deviate from the Mini PCIe standard, often in the electrical specification, verify the module datasheet for conformance before connecting it to the Genesys ZU.

10.2 Low-Pin Count FMC Connector

The Genesys ZU includes an FPGA Mezzanine Card (FMC) Standard-conforming carrier card connector that enables connecting mezzanine modules compliant with the same standard. Genesys ZU-based designs can now be easily extended with custom or off-the-shelf high-performance modules.

The actual connector used is a 160-pin Samtec ASP-134603-01, the low-pin count, 10mm stacking height variant of the standard. All user defined signals are bonded to the PL-side of the MPSoC to HP banks 64 and 65. On the 5EV variant the multi-gigabit transceiver lane is also wired to the PL-side GTH transceiver, sharing the channel with the SFP+ slot.* The 34 differential pairs are powered by the Genesys ZU VADJ rail adjustable in the 1.2 V - 1.8 V range. There is also a 12 V rail wired to the FMC connector, which can supply up to 1 A to the mezzanine card.

FMC mezzanine cards are NOT hot-swappable. Connecting or disconnecting a card from the Genesys ZU while the board is powered on may cause damage to the mezzanine card and/or the board, and is to be avoided.

The UltraScale+ HP banks support the highest data rates available in the non-GT I/O architecture over the FMC connector.

The pin-out of the FMC connector can be found in the XDC constraints file available on Digilent Reference. The schematic also shows the mapping between FMC connector pins and FPGA pins. Keep in mind that pin designators for the connector are not the same as pin designators for the FPGA specified in the XDC constraints file. For example, the connector pin with designator H28 and named LA24_P is wired via net FMC_LA24_P to the FPGA pin with designator AF7 and named IO_L11P_T1U_N8_GC_64. In the constraints file FMC_LA24_P will need to be location constrained to AF7.

For FMC designs which use FMC_LA_07_P/_N and/or FMC_LA15_P/_N lines with an I/O standard which needs DCI, please make sure you add the DCIRESET primitive to the respective designs. Refer to the UltraScale Architecture SelectIO Resources User Guide (ug571) chapter “Special DCI Requirements in Some Banks” for more information.

10.2.1 Gigabit Data Signals*

For above-gigabit speed rates on the 5EV variant, the GTH transceivers* in the MPSoC can be used. The FMC Low-Pin Count has a single transceiver lane, DP0. A transceiver lane includes a receive pair (DP0_M2C) and a transmit pair (DP0_C2M). DP0 is wired to channel 3 of GTH Quad 224*, which is shared with the SFP+ slot* through a high-speed multiplexer. Therefore, the SFP+ slot* and the FMC gigabit* features cannot be used simultaneously. See the High-Speed Multiplexer subsection on how to switch between the two.

Furthermore, since SFP+, FMC Gigabit and HDMI Source/Sink share the same GTH Quad, it is up to the IP implementations to properly share the Quad primitives amongst themselves. For example, HDMI Subsystem can implement both HDMI Source and Sink simultaneously, but does not have sharing options with the Ethernet Subsystem, even though SFP+ is on a separate GTH Channel.

Therefore, the SFP+*, FMC Gigabit* and HDMI* features cannot be used simultaneously on the Genesys ZU-5EV.

The FMC user defined pins are not affected by this limitation.

Table 10.2.1.1 shows how the FMC gigabit signals are mapped to pins and GTH primitives. Refer to the UltraScale Architecture GTH Transceivers User Guide (ug576) for more information.

Table 10.2.1.1: FMC Gigabit Signals Mapping

| Quad | Primitive | Pin type | Pin | FMC signal | |

|---|---|---|---|---|---|

| 224 | GTHE4_CHANNEL | X0Y7 | MGTHTXP/N3 | N4/N3 | DP0_C2M_P/N |

| MGTHRXP/N3 | P2/P1 | DP0_M2C_P/N | |||

GTH Quad 224* has two reference clock inputs, one of which is dedicated to HDMI Sink* (MGTREFCLK1P/N). The other (MGTREFCLK0P/N) is generated by a Silicon Labs Si5342A-D-GM IC46* and can be used for FMC applications. This oscillator outputs a free-running 156.25 MHz reference clock by default.

Reference clock GBTCLK0-M2C from the FMC module is wired to input 1 of oscillator IC46*. The oscillator can be configured to synchronize to this input and use its output as reference in the GTH transceiver. Refer to section GTH Reference Clocks for more information.

10.2.2 Routing Lengths

The FMC specification outlines rules on what length mismatch is permissible on different lanes. The signals can be grouped into two categories: Gigabit and User I/O. Differential gigabit lanes permit 1 ps intra-pair mismatch and does not limit inter-pair length mismatch. The reason for the latter is that multi-gigabit protocols have some sort of de-skew mechanism to re-align data between lanes.

User I/O is different in that it is mostly used with source-synchronous interfaces, where the bit clock it transmitted alongside and used by the receiver to sample all data lanes of the interface. Therefore, inter-pair skew must be controlled. The maximum allowed inter-pair skew is dependent on the target data rate, but the specifications recommend 10% of the UI (unit interval) reserved for inter-pair skew. Intra-pair skew is not limited by the specification, but if differential I/O is targeted it is still a good practice. The Genesys ZU targets a maximum data rate of 1600 Mbps or 625 ps UI.

The specifications are silent on whether the inter-pair skew budget is per-carrier/mezzanine or for the whole system. The routed trace lengths in table 10.2.2.2 below can be used to match a mezzanine card to the Genesys ZU and better control the skews. Just keep in mind, that the lengths below are for PCB traces only and one would need to add FPGA package delays too.

Table 10.2.2.1: Maximum length mismatch including MPSoC package delay.

| Signal Group | Length matching | |

|---|---|---|

| Intra-pair | Inter-pair | |

| LA[00-33], CLK[0-1]_M2C | 1 mm | 10 mm |

| DP0*, GBTCLK0* | 0.14 mm | 100 mm |

- Table 10.2.2.2: PCB Trace Lengths of FMC User I/O

-

Net Name Routed Length (mm) FMC_CLK0_M2C_N 198.586 FMC_CLK0_M2C_P 198.204 FMC_CLK1_M2C_N 128.278 FMC_CLK1_M2C_P 129.73 FMC_LA00_CC_N 177.621 FMC_LA00_CC_P 177.811 FMC_LA01_CC_N 174.612 FMC_LA01_CC_P 174.557 FMC_LA02_N 178.628 FMC_LA02_P 177.951 FMC_LA03_N 176.451 FMC_LA03_P 176.412 FMC_LA04_N 174.959 FMC_LA04_P 174.956 FMC_LA05_N 177.904 FMC_LA05_P 178.977 FMC_LA06_N 176.407 FMC_LA06_P 176.296 FMC_LA07_N 179.343 FMC_LA07_P 178.38 FMC_LA08_N 179.016 FMC_LA08_P 179.484 FMC_LA09_N 180.186 FMC_LA09_P 179.421 FMC_LA10_N 176.149 FMC_LA10_P 175.163 FMC_LA11_N 177.113 FMC_LA11_P 176.892 FMC_LA12_N 177.504 FMC_LA12_P 176.827 FMC_LA13_N 178.743 FMC_LA13_P 178.96 FMC_LA14_N 176.243 FMC_LA14_P 176.056 FMC_LA15_N 177.971 FMC_LA15_P 178.026 FMC_LA16_N 177.495 FMC_LA16_P 178.309 FMC_LA17_CC_N 174.562 FMC_LA17_CC_P 175.465 FMC_LA18_CC_N 173.047 FMC_LA18_CC_P 173.477 FMC_LA19_N 175.163 FMC_LA19_P 175.107 FMC_LA20_N 177.942 FMC_LA20_P 178.29 FMC_LA21_N 169.335 FMC_LA21_P 170.321 FMC_LA22_N 177.875 FMC_LA22_P 178.415 FMC_LA23_N 170.471 FMC_LA23_P 169.982 FMC_LA24_N 175.309 FMC_LA24_P 174.808 FMC_LA25_N 167.794 FMC_LA25_P 168.73 FMC_LA26_N 179.224 FMC_LA26_P 180.207 FMC_LA27_N 167.765 FMC_LA27_P 168.692 FMC_LA28_N 178.262 FMC_LA28_P 177.827 FMC_LA29_N 172.521 FMC_LA29_P 172.147 FMC_LA30_N 177.974 FMC_LA30_P 178.54 FMC_LA31_N 174.063 FMC_LA31_P 174.985 FMC_LA32_N 173.177 FMC_LA32_P 173.666 FMC_LA33_N 177.074 FMC_LA33_P 177.976

10.2.3 Simulation models

S-parameter models for differential User I/O nets can be downloaded from here. The modeled transmission line includes FMC connector J48 and PCB traces.

S-parameter models for differential Gigabit nets can be downloaded from here. The modeled transmission line includes FMC connector J48, PCB segment, high-speed multiplexer IC38, and another PCB segment.

10.3 Zmod

The Zmod port uses the SYZYGY Standard interface to communicate with installed SYZYGY pods. The port is compatible with version 1.1 of the SYZYGY specification from Opal Kelly.

Attachment detection is implemented by the Platform MCU and pod presence is communicated to the MPSoC over the SYZYGY_DETECTED signal. For now, it is up to the MPSoC to read the port's SYZYGY DNA and implement SmartVIO functionality by requesting a compatible voltage on the VADJ rail. SYZYGY DNA is accessible on branch 5 of the I2C multiplexer on the main I2C bus at address 0110000b.

Zmods/SYZYGY pods are NOT hot-swappable. Connecting or disconnecting a pod from the Genesys ZU while the board is powered on may cause damage to the pod and/or the board, and is to be avoided.

Each SYZYGY Standard interface contains 14 single-ended I/O pins (2 of which I2C), 8 differential I/O pairs (which can alternatively be used as 16 additional single-ended I/O pins), and two dedicated differential clocks - one for input and one for output. The Zmod port is wired to PL-side MPSoC banks powered by the VADJ rail, sharing them with FMC signals. Therefore if both an FMC mezzanine card and a Zmod are connected to the Genesys ZU, a common voltage supported by both needs to be chosen for VADJ. The differential pairs were prioritized and wired to HP banks, allowing the maximum data rates supported by the SelectI/O architecture. However, the single-ended pins are wired to an HD bank, limiting the data rate to 250 Mb/s according to the Zynq UltraScale+ MPSoC Data Sheet: DC and AC Switching Characteristics (ds925). Template constraints for the Zmod port can be found in the Genesys ZU's Master XDC file, available through Digilent's digilent-xdc repository on Github.

The two standoffs located on the sides of the Zmod port, on the top side of the Genesys ZU board, are hexagonal, 5 mm tall with M2.5 x 0.45 internal threaded holes. For mounting Zmods on Genesys ZU, two screws with M2.5 x 0.45 thread and 3mm thread length would be needed.

For more information on the SYZYGY standard, see syzygyfpga.io.

10.3.1 Carrier-Pod Compatibility

The Genesys ZU Zmod port is compatible with a variety of different SYZYGY pods. Information required to determine if the Genesys ZU is compatible with a certain pod is summarized in Table 10.3.1.1 below.

Table 10.3.1.1: SYZYGY Compatibility

| Parameter | Port A (STD) |

|---|---|

| Port Type | Standard |

| Single-Width | |

| Total 5V Supply Current | 1 A |

| Total 3.3V Supply Current | 3.5 A (shared with FMC) |

| VIO Supply Voltage Range | 1.2V to 1.8V |

| Total VIO Supply Current | 2.1 A (shared with FMC) |

| Port Groups | Group 1: A |

| I/O Count | 28 total (8 DP) |

| Length Matching | 10 mm inter-pair, 1mm intra-pair |

The routed trace lengths in table 10.3.1.2 below can be used to match a custom pod to the Genesys ZU and better control the skews. Just keep in mind, that the lengths below are for PCB traces only and one would need to add FPGA package delays too.

- Table 10.3.1.2: PCB Trace Lengths of SYZYGY Nets

-

Net Name Routed Length (mm) SYZYGY_D0_N 169.734 SYZYGY_D0_P 169.623 SYZYGY_D1_N 167.656 SYZYGY_D1_P 167.66 SYZYGY_D2_N 166.912 SYZYGY_D2_P 167.342 SYZYGY_D3_N 170.138 SYZYGY_D3_P 170.266 SYZYGY_D4_N 173.062 SYZYGY_D4_P 173.247 SYZYGY_D5_N 171.113 SYZYGY_D5_P 171.168 SYZYGY_D6_N 171.741 SYZYGY_D6_P 171.659 SYZYGY_D7_N 172.473 SYZYGY_D7_P 172.081 SYZYGY_OUT_CLK_N 170.141 SYZYGY_OUT_CLK_P 170.254 SYZYGY_S16 172.55 SYZYGY_S17 172.768 SYZYGY_S18 172.152 SYZYGY_S19 172.968 SYZYGY_S20 172.805 SYZYGY_S21 171.704 SYZYGY_S22 171.686 SYZYGY_S23 170.673 SYZYGY_S24 171.557 SYZYGY_S25 171.896 SYZYGY_S26 171.25 SYZYGY_S27 171.509 SYZYGY_IN_CLK_N 173.034 SYZYGY_IN_CLK_P 172.466

10.3.2 Simulation Models

S-parameter models for differential and single-ended SYZYGY nets can be downloaded from here. The modeled transmission line includes Zmod connector J5 and PCB traces.

10.4 Pmod

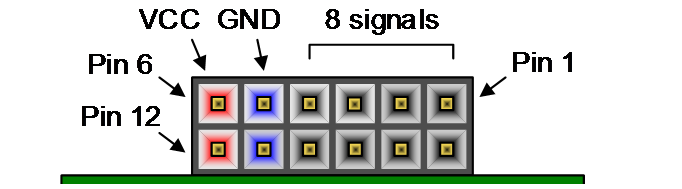

Pmod ports are 2×6, right-angle, 100-mil spaced female connectors that mate with standard 2×6 pin headers. Each 12-pin Pmod port provides two 3.3V VCC signals (pins 6 and 12), two Ground signals (pins 5 and 11), and eight logic signals, as shown in Figure 10.4.1 below. For more information regarding the power supply specifications of the Pmod ports, refer to the Digilent Pmod™ Interface Specification, “Power Supply” section.

Digilent produces a large collection of Pmod accessory boards that can attach to the Pmod ports to add ready-made functions like A/D’s, D/A’s, motor drivers, sensors, and other functions. See www.digilentinc.com for more information. The vivado-library repository on the Digilent Github contains pre-made IP cores for many of these Pmods that greatly reduce the work of integrating them into your project. This repository's hierarchies branch contains additional scripts and sources that can be used to speed up the process of integrating these cores. See the Pmod-related tutorials on the Genesys ZU Resource Center for help using them.

- PMODS JA, JB, JC, JD

-

Dual Digital/Analog PMOD PMOD JB PMOD JC PMOD JD JA1_P:W10 JB1:AE13 JC1:E13 JD1:E15 JA2_P:AA11 JB2:AG14 JC2:G13 JD2:A14 JA3_P:AB10 JB3:AH14 JC3:B13 JD3:B15 JA4_P:Y9 JB4:AG13 JC4:D14 JD4:F15 JA1_N:Y10 JB7:AE14 JC7:F13 JD7:E14 JA2_N:AA10 JB8:AF13 JC8:C13 JD8:B14 JA3_N:AB9 JB9:AE15 JC9:C14 JD9:D15 JA4_N:AA8 JB10:AH13 JC10:A13 JD10:A15

10.5 Dual Digital/Analog Pmod

On the Genesys ZU, one of the Pmod connectors is not like the others. Designated by JA, the Pmod connector is wired to pins that can serve as auxiliary inputs to the system monitor ADC inside the MPSoC. These pins are in a VADJ-powered bank, so the VCC pins are not powered from the 3.3 V rail, like on regular Pmods, but from VADJ. VADJ on the Genesys ZU is in the 1.2 V - 1.8 V range. Pins 1-7, 2-8, 3-9, 4-10 are paired and routed differentially. Although these pins can be used in digital mode, the particularities of this connector must be taken into account when connecting Pmod modules to it.

11 Basic I/O

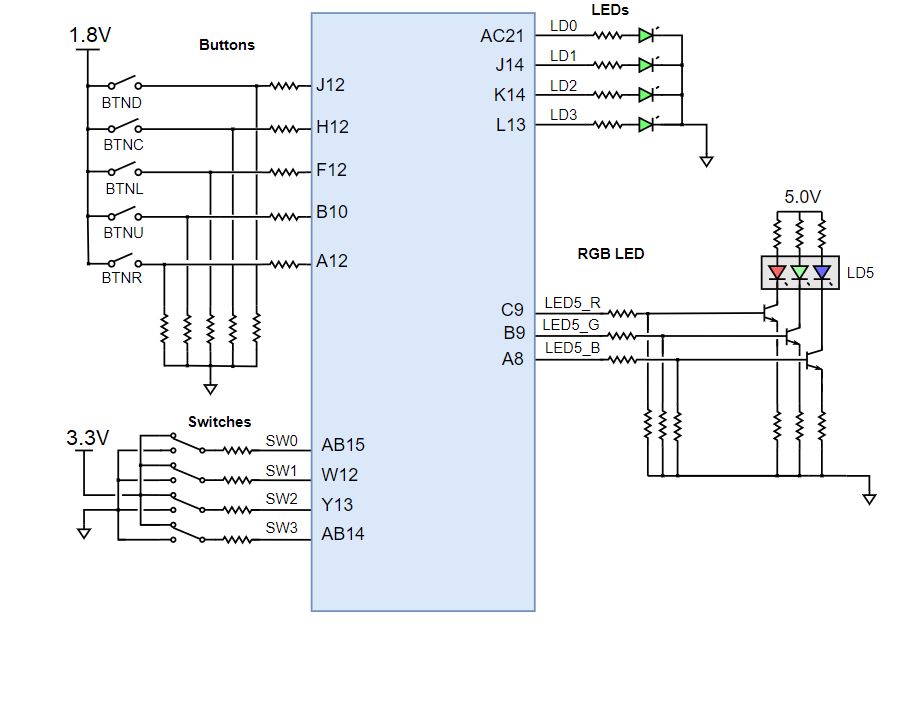

The Genesys ZU includes five push-buttons, four slide switches, one tri-color LED and four green LEDs connected to the Zynq PL, as shown in Figure 11.1 below. These I/Os are connected to the Zynq via series resistors to prevent damage from inadvertent short circuits (a short circuit could occur if a pin assigned to a push-button was inadvertently defined as an output). The five push-buttons are arranged in a plus-sign configuration (center, left, right, up and down buttons, respectively).

Genesys ZU also has two push-buttons and one green LED connected to the Zynq PS: push-buttons BTN0 and BTN1 are connected to MIO11 and MIO10, respectively, and the green LED is connected to MIO21.

11.1 Push-Buttons

The push-buttons are “momentary” switches that normally generate a low output when they are at rest, and a high output only when they are pressed.

11.2 Slide Switches

The slide switches generate constant high or low inputs depending on their position: when the slide is in a low position (i.e. close to the lower board edge), the generated input is low; when the slide is in a high position (i.e. close to the center of the board), the generated input is high.

11.3 Tri-Color LED